Research progress in ecological treatment of expansive soil

-

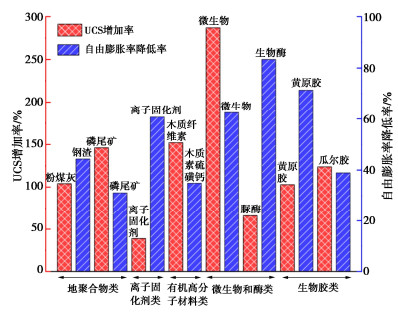

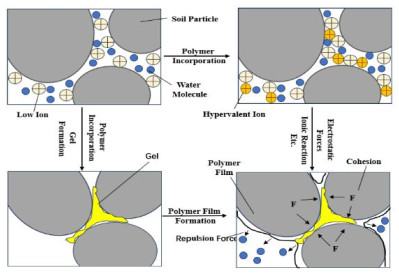

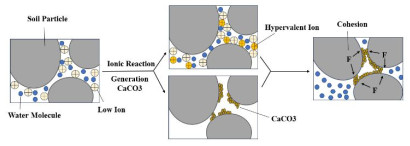

摘要: 膨胀土是一种遇水急剧膨胀变形、失水迅速收缩开裂的问题土,需对其进行治理以满足工程要求。对近年来新发展的膨胀土生态治理材料进行了归纳、总结,并根据其组分、特点分为地聚合物类、离子固化剂、有机高分子材料类、微生物与酶类和生物胶类,并阐述了各类固化剂的材料特点、固化效果及作用机理,均符合新时代发展要求,可作为一种可持续的、环保的、多功能的技术大范围推广应用,最后从生态治理和推广应用角度探讨了目前需要克服的问题。Abstract: The expansive soil is a kind of problematic soil that rapidly expands and deforms when encountering water and rapidly shrinks and cracks when losing water. It needs to be treated to meet the engineering requirements. The newly developed ecological treatment materials for the expansive soil in recent years are summarized and categorized, and the are classified according to their components and characteristics into-geopolymer, ion curing agent, organic polymer material, microorganism and enzyme, and biopolymer. The material characteristics, treatment effectiveness, and stabilization mechanisms of various treatment materials are elaborated, and they all meet the requirements of the new era and can be widely promoted and applied as a sustainable, environmentally friendly and versatile technology. Finally, the urgent issues that need to be addressed from the perspectives of ecological governance and promotion are discussed.

-

0. 引言

沿海地区的水下地下工程建设不可避免地会受到的地下水渗流影响[1],将导致施工区域软土地基沉降,造成周围建筑物和地面的不均匀沉降。为保持原有地层稳定,人工冻结技术在岩土工程中广泛应用[2],包括海底隧道和城市地铁建设[3]。流速较大条件下易出现冻结壁不闭合的现象[4],不能满足施工设计的要求。

在人工冻结过程中,确定地层的冻结范围是非常重要的。基于热势叠加理论,Hu等[5]和Pimentel等[6]推导了静水和渗流条件下不同冻结形式下的稳态温度场的理论公式,用来预测圆形冻结壁的厚度和平均温度[7]。地下水渗流的存在使等温线向下游移动,下游冻结壁厚度大于上游[8]。但现有的解析解不能揭示多孔介质冻结过程中渗流与各物理场的耦合机制。

当存在地下水渗流时,水流携带的热量导致冻结区的解冻[9],研究渗流条件下冻结过程中的多场耦合机制是必要的。考虑冻结过程中多场耦合变化,建立了渗流条件下人工冻结过程多场耦合数值模型[10]。饱和土的冻结过程涉及多场、多相,针对沿海地区地下水含盐量高的问题[11],在多孔介质理论框架下建立多场宏观模型,模拟地下水渗流条件下的冻结过程。

本文建立了渗流条件下砂地层在人工冻结时的水-盐-热-力耦合模型。充分考虑非对流通量对传热传质的影响,固体颗粒对盐的解吸和吸附作用,以准确模拟人工冻结过程。采用Navier-Stokes方程来考虑渗流过程中流体的动量守恒,研究了单管冻结条件下,不同渗流速度下滨海砂地层中各组分的分布规律。

1. 控制方程

1.1 固体基质质量守恒方程

多孔介质中固体基质的质量守恒方程为[12]:

1(1−n)∂n∂t+1(1−wsp)∂wsp∂t+βsT∂T∂t=βsP∂Pl∂t+∂εv∂t。 (1) 式中:wsp为固体颗粒吸附盐的质量分数;T为温度;Pl为孔隙水力压力。

1.2 水分守恒方程

多孔介质中水分质量守恒方程的展开式为

nSl(1−wlp)βlpρl∂Pl∂t+div(ρlwql)−div(jlp)=−∂mi∂t−∂mlp∂t+nρlw∂Si∂t+nρlwSp∂t−Slρlw∂n∂t+nSlρl[(1−wlp)βlw+1]∂wlp∂t−nSlρlw∂εv∂t+(1−wlp)nSlβlTρl∂T∂t。 (2) 式中:βlp为液相压缩率;βlT为液体热膨胀系数;βlw为浓度依赖系数;∂mi/∂t为冰的结晶速率;∂mlp/∂t为结晶盐水合物的形成速率;jlp为盐在液相中的非对流通量;ρlw为液态的水密度;ρl为液相的密度;wlp溶解盐的质量分数。

冰的质量守恒方程为[13]

1n∂n∂t+1Si∂Si∂t+∂εv∂t=1nSiρi∂mi∂t, (3) 式中,ρi为冰的密度。

1.3 盐分守恒方程

考虑冻结多孔介质液相中盐溶液的非对流通量,溶液的质量守恒为

∂(nSlρlp)∂t+div(nSlρlpvl)+div(jlp)=−∂mp∂t−∂mlp∂t。 (4) 式中:jlp为冻土中盐的非对流通量;∂mp/∂t为结晶盐的相变速率。

可得到展开的溶液质量守恒方程:

1n(1−ρswspρlwlp)∂n∂t−1Sl∂Si∂t−1SlSp∂t+∂εv∂t+[βlp+(1−n)wspρsnSlρlwlpβsP]∂Pl∂t+(1−wlpβlw)wlp∂wlp∂t+1wlp(1−n)ρsnSlρl∂wsp∂t−[(1−n)wspρsnSlρlwlpβsT+βlT]∂T∂t=div(ρlwlpql)+div(jlp)−∂mp∂t−υlMlMp∂mp∂tnSlρlwlp。 (5) 式中:wlp为液相中盐的质量分数;jlp冻为土中盐的非对流通量;ql为液相相对流动体积;Ml为液体的摩尔质量;Mp为结晶盐的摩尔质量。

考虑多孔介质中盐的吸附-解吸效应,冻土中盐分的沉积动力学公式为

(1−n)ρs∂wsp∂t + div[(1−n)ρsvs]=kadnSlρlwlp−kde(1−n)ρswsp, (6) 式中,kad和kde分别为吸附系数和解吸系数。

结晶盐的质量守恒方程为[13]

1n∂n∂t+1Sp∂Sp∂t+∂εv∂t=1nρpSp∂mp∂t, (7) 式中:ρp为结晶盐的密度。

1.4 能量守恒方程

多孔介质冻结过程中的能量守恒与热容和热传导度有关,能量守恒方程表示为

[(1−n)ρscs+nSlρlcl+nSiρicii+nSpρpcpp]∂T∂t+div[(clpjlp−ρlclql)(T−T0)−λeff∇T]=Lwi∂mi∂t+Lsc∂mp∂t+LlpυlMlMp∂mp∂t。 (8) 式中:g为重力加速度矢量;λeff为冻土有效导热系数;cs,cl,cii和cpp分别代表固体颗粒、液相、冰和结晶盐的热容;Lwi,Llp,Lsc分别为水、冰的相变潜热、自由水、结合水相变潜热和溶液-结晶盐的相变潜热。

1.5 动量守恒方程

人工冻结过程中的各向异性和渗流状态影响着砂土地层的冻结状态,在动量守恒中引入Navier-Stokes方程来描述渗流的动量守恒。土体冻结过程中π相的动量守恒方程为

ρπnπdvπdt−div(nπσπ)−ρπnπgπ=˙mπ。 (9) 式中:σπ为π相的应力张量;˙mπ为π相与其他相的动量交换,gπ为π相的体积密度。

可得到土体的动量守恒方程:

nρl(Fg−∇Plρl+μl∇2vl)−div(σ′+SlPl+SiPi+SpPp)−[(1−n)ρs+nSlρl+nSiρi+nSpρp]g=˙mπ。 (10) 式中:Fg为单位质量力;μl为液相的动力黏度;Pi为冰压力;Pp为孔隙中盐结晶压力;σ′为有效应力。

1.6 边界条件

将耦合方程(1)~(3),(5)~(8),(10)代入COMSOL Multiphysics进行求解。边界与外部存在热对流和热交换和水、盐供应。要解耦合方程,必须满足下列边界条件:

(ρlwql−jlp)⋅n=¯Pl , (ρlwlpql+jlp)⋅n=¯wlp , [(ρlwclwql+clpjlp)⋅(T−T0)−λeff∇T]⋅n=¯T , σ⋅n=¯εv 。} (11) 2. 理论验证

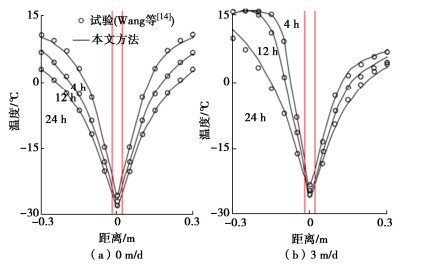

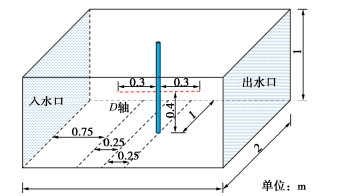

结合Wang等[14]的渗流条件下人工冻结过程温度场验证本文理论模型。模型试验如图 1所示,箱体中间设置一根外径为42 mm的冷冻管。整个模型的初始温度为10℃,冻结管的初始温度为-30℃。在箱体0.4 m处设置D轴。表 1给出了本研究使用的物理参数,模型试验所用砂土的干密度为1612 kg/m3,孔隙率为0.33,渗透系数为2.28×10−4 m/s。理论模型中D轴的温度分布结果与试验结果对比如图 2所示。可以看出理论分析结果与模型试验结果基本一致。

名称 符号 值 单位 名称 符号 值 单位 吸附系数 kad 2.5×10-4 s-1 水冰相变潜热 Lwi 6.01 kJ·mol-1 解吸系数 kde 1.5×10-4 s-1 液相压缩率 βlp 1×10-7 kPa-1 固相热膨胀系数 βsT 7.8×10-6 K-1 液体热膨胀系数 βlT 2.1×10-4 K-1 浓度依赖系数 βlw 0.6923 — 液态水密度 ρlw 1000 kg·m-3 冰的密度 ρl 917 kg·m-3 摩尔气体常数 R 8.2 J·mol-1·K-1 结晶盐密度 ρp 1460 kg·m-3 结晶盐的物质的量 Mp 0.142 kg·mol-1 盐的动力学参数 Kp 1.8×10-3 s-1 液相的物质的量 Ml 0.018 kg·mol-1 吸湿膨胀系数 βs 1.5×10-4 — 固体热容 cs 850 J·kg-1·K-1 冰的动力学参数 Ki 5.82×10-3 s-1 冰的热容 cii 2090 J·kg-1·K-1 自由水结合水相变潜热 Llp 73.04 kJ·mol-1 结晶盐的热容 cpp 1743 J·kg-1·K-1 盐、结晶盐相变潜热 Lsc 2.34 kJ·mol-1 固相压缩率 βsp 2×10-4 kPa-1 3. 参数研究

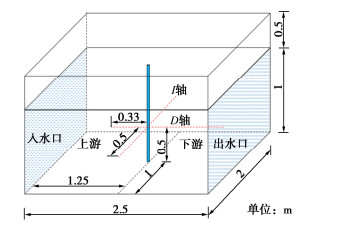

通过参数化研究,分析了不同渗流速度和温度梯度下各组分在砂层中的空间分布。砂土层模型试验渗流如图 3所示。模型边界目标参数如表 2所示,砂层中wlp0和T0的初始值分别为0.005和10℃。冻结管壁温度设为-27℃,渗流只存在于砂层底部。冰饱和度Si、结晶盐饱和度Sp、吸收盐含量wsp0的初始条件和边界条件均为0。选取图 2中位于砂层中4条轴线Dc,Ds,Ic,Is,绘制温度、冰、盐、位移分布图。

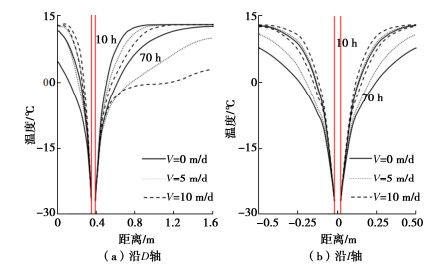

表 2 参数分析中使用的目标参数Table 2. Target parameters used in parametric studies项目 Pl0/kPa Tp/℃ T0/℃ wlp0 wlp 渗流/(m·d-1) 试验 γwΔH -30 10 — — 0, 3 渗流 γwΔH -27 13 0.005 0.005 0, 5, 10 不同渗流速度的下部砂层中温度沿D轴和I轴分布情况如图 4所示。随着渗流速度从0 m/d增加到10 m/d,在人工冻结70 h后,在沿着D轴方向上的砂层上游的温度增加8.8℃,下游最高降低了13.2℃,如图 4(a)所示。当渗流速度从0 m/d增加到10 m/d,人工冻结70 h后,冻结管左右两侧的沿着I轴的温度升高了6.2℃,如图 4(b)所示。

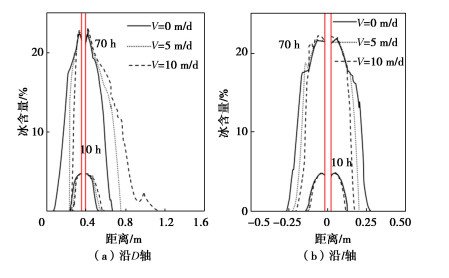

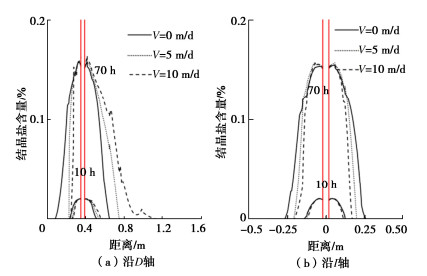

不同渗流速度对下部砂层中含冰量沿D轴和I轴分布情况如图 5所示。渗流导致水分开始冻结的位置沿着D轴向下游移动。随着渗流速度从0 m/d增加到10 m/d,在人工冻结70 h后,在沿着D轴方向上的砂层上游水分冻结的位置向下游移动了63.5%,下游中水分冻结的位置向下游移动了173.2%,如图 5(a)所示。当渗流速度从0 m/d增加到10 m/d,即人工冻结70 h后,冻结管左右两侧的沿着I轴的水分冻结范围缩减了37.8%,如图 5(b)所示。

不同渗流速度对下部砂层中结晶盐量沿D轴和I轴分布情况如图 6所示。图 6(a)给出了沿着渗流方向上结晶盐含量随着渗流和冻结时间变化的分布情况,盐分析出的位置沿着D轴向下游移动。随着渗流速度从0 m/d增加到10 m/d,在人工冻结70 h后,在沿着D轴方向上的砂层上游盐分开始析出的位置向下游移动了65.1%,下游中盐分开始析出的位置向下游移动了182.7%。当渗流速度从0 m/d增加到10 m/d,即人工冻结70 h后,冻结管左右两侧的沿着Ⅰ轴的盐分的析出范围缩减了42.7%,如图 6(b)所示。

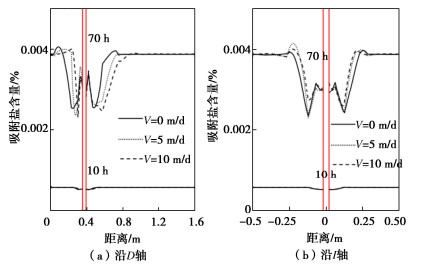

不同渗流速度对下部砂层吸附盐含量沿D轴和I轴分布的影响如图 7所示。渗流削弱了下游的盐分吸附能力。随着渗流速度从0 m/d增加到10 m/d,在人工冻结70 h后,在沿着渗流的D轴方向上,砂层上游的吸附盐突变位置向下游移动了52%,下游的吸附盐突变位置向下游移动了32%,如图 7(a)所示。当渗流速度从0 m/d增加到10 m/d,即人工冻结70 h后,冻结管左右两侧的沿着I轴的吸附盐突变范围向冻结管方向缩小了16.2%,如图 7(b)所示。

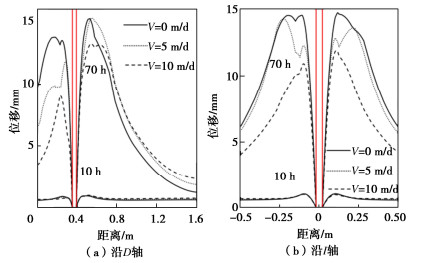

不同渗流速度对下部砂层中土体位移沿D轴和I轴分布情况如图 8所示。随着冻结时间的增加,砂地层在冻胀和盐胀的作用下土体位移逐渐增加。随着渗流速度从0 m/d增加到10 m/d,在人工冻结70 h后,在沿着D轴方向上的砂层上游的土体位移降低了33.4%,下游的土体位移降低了14.3%,如图 8(a)所示。当渗流速度从0 m/d增加到10 m/d,即人工冻结70 h后,冻结管左右两侧的沿着I轴的土体位移降低了23.1%,如图 8(b)所示。

4. 结论

本文推导了渗流条件滨海砂土层人工冻结的水-盐-热-力学耦合模型。利用COMSOL Multiphysics软件对导出的微分方程进行求解。理论计算结果与文献中实验室模型试验结果吻合较好,验证了模型的准确性。通过参数分析,研究了不同渗流速度下的砂地层中各组分的空间分布情况。得出以下3点结论。

(1)在砂层冻结后,地层中的孔隙被堵塞,砂层底部上游的高温流体穿过地层的左右两侧下游流动。随着渗流速度从0 m/d增加到10 m/d,在人工冻结70 h后,砂层上游的最高温度增加8.8℃。冻结管左右两侧的土体位移降低了23.1%,渗流削弱了冻结效果,减小了冻结导致的土体位移。

(2)在垂直于渗流方向上,冻结管左右两侧的冰、结晶盐对称分布。在人工冻结70 h后,随着渗流速度从0 m/d增加到10 m/d,砂层上游水分冻结位置向下游移动63.5%,下游中水分冻结位置向下游移动173.2%,冻结管左右两侧的水分冻结范围缩减37.8%。

(3)冻结区域中盐分的吸附能力是被抑制的。随着渗流速度从0 m/d增加到10 m/d,在人工冻结70h后,砂层上游的吸附盐突变位置向下游移动52%,下游的吸附盐突变位置向下游移动32%,冻结管左右两侧的吸附盐突变范围向冻结管方向缩小16.2%。

-

-

[1] 冷挺, 唐朝生, 徐丹, 等. 膨胀土工程地质特性研究进展[J]. 工程地质学报, 2018, 26(1): 112-128. LENG Ting, TANG Chaosheng, XU Dan, et al. Advance on the engineering geological characteristics of expansive soil[J]. Journal of Engineering Geology, 2018, 26(1): 112-128. (in Chinese)

[2] 杨和平, 李宇峙, 陈虔礼. 膨胀土路基病害及防治措施[J]. 公路, 1995, 40(5): 8-12. YANG Heping, LI (Yu)(Shi| Zhi), CHEN Qianli. Disease of expansive soil subgrade and its prevention measures[J]. Highway, 1995, 40(5): 8-12. (in Chinese)

[3] 杨和平, 章高峰, 郑健龙, 等. 膨胀土填筑公路路堤的物理处治技术[J]. 岩土工程学报, 2009, 31(4): 491-500. doi: 10.3321/j.issn:1000-4548.2009.04.001 YANG Heping, ZHANG Gaofeng, ZHENG Jianlong, et al. Physical treating techniques of highway embankments filled with expansive soils[J]. Chinese Journal of Geotechnical Engineering, 2009, 31(4): 491-500. (in Chinese) doi: 10.3321/j.issn:1000-4548.2009.04.001

[4] 徐永福, 程岩, 肖杰, 等. 膨胀土滑坡和工程边坡新型防治技术研究[J]. 岩土工程学报, 2022, 44(7): 1281-1294. doi: 10.11779/CJGE202207009 XU Yongfu, CHENG Yan, XIAO Jie, et al. New prevention and control technology for expansive soil slopes[J]. Chinese Journal of Geotechnical Engineering, 2022, 44(7): 1281-1294. (in Chinese) doi: 10.11779/CJGE202207009

[5] 庄心善, 杨文博, 胡其志. 磷尾矿改良合肥膨胀土强度试验研究[J]. 科学技术与工程, 2018, 18(5): 281-284. doi: 10.3969/j.issn.1671-1815.2018.05.048 ZHUANG Xinshan, YANG Wenbo, HU Qizhi. Experimental study on strength improvement of Hefei expansive soil by phosphorus tailings[J]. Science Technology and Engineering, 2018, 18(5): 281-284. (in Chinese) doi: 10.3969/j.issn.1671-1815.2018.05.048

[6] 李丽华, 黄畅, 李文涛, 等. 稻壳灰-矿渣固化膨胀土力学与微观特性研究[J]. 岩土力学, 2023, 44(10): 2821-2832, 2842. LI Lihua, HUANG Chang, LI Wentao, et al. Study on mechanical and microscopic characterization of expansive soil solidified by rice husk ash-granulated blast furnace slag[J]. Rock and Soil Mechanics, 2023, 44(10): 2821-2832, 2842. (in Chinese)

[7] 刘清秉, 项伟, 崔德山, 等. 离子土固化剂改良膨胀土的机理研究[J]. 岩土工程学报, 2011, 33(4): 648-654. LIU Qingbing, XIANG Wei, CUI Deshan, et al. Mechanism of expansive soil improved by ionic soil stabilizer[J]. Chinese Journal of Geotechnical Engineering, 2011, 33(4): 648-654. (in Chinese)

[8] HE S, YU X B, BANERJEE A, et al. Expansive soil treatment with liquid ionic soil stabilizer[J]. Transportation Research Record: Journal of the Transportation Research Board, 2018, 2672(52): 185-194. doi: 10.1177/0361198118792996

[9] 黄河, 施斌, 刘瑾, 等. STW型生态土壤稳定剂改性膨胀土水理性质试验研究[J]. 岩土工程学报, 2008, 30(8): 1236-1240. HUANG He, SHI Bin, LIU Jin, et al. Water-physical properties of expansive soils modified by STW ecotypic soil stabilizer[J]. Chinese Journal of Geotechnical Engineering, 2008, 30(8): 1236-1240. (in Chinese)

[10] 孟令超, 朴淼, 张鸿秋, 等. 干湿循环条件下木质素改良膨胀土胀缩特性[J]. 工程地质学报, 2023, 31(2): 386-396. MENG Lingchao, PIAO Miao, ZHANG Hongqiu, et al. Swelling and shrinkage behaviour of expansive soil ameliorated by calcium lignosulphonate during wetting-drying cycles[J]. Journal of Engineering Geology, 2023, 31(2): 386-396. (in Chinese)

[11] 魏然, 张丽雅, 肖智睿, 等. 基于MICP技术的膨胀土变形控制机理研究[J]. 岩土工程学报, 2023, 45(增刊1): 92-96. WEI Ran, ZHANG Liya, XIAO Zhirui, et al. Study on deformation control mechanism of expansive soil based on MICP technology[J]. Chinese Journal of Geotechnical Engineering, 2023, 45(S1): 92-96. (in Chinese)

[12] LI M, TAO X, LANG C, et al. Enzyme-induced carbonate precipitation using yellow soybean for eco-friendly treatment of expansive soils[J]. International Journal of Geomechanics, 2024, 24(3): 04024007.

[13] 王天亮, 王林, 刘松松, 等. 黄原胶和瓜尔胶改良膨胀土力学特性试验研究[J]. 中国铁道科学, 2023, 44(2): 1-10. WANG Tianliang, WANG Lin, LIU Songsong, et al. Experimental study on mechanical properties of expansive soil improved by xanthan gum and guar gum[J]. China Railway Science, 2023, 44(2): 1-10. (in Chinese)

[14] FIRMANSYAH D A, SOMANTRI A K, SIHOMBING A V R, et al. Optimization of the Atterberg Limits on expansive soil stabilized with chitosan biopolymer[J]. E3S Web of Conferences, 2024, 479: 06002.

[15] SEYREK E. Engineering behavior of clay soils stabilized with class C and class F fly ashes[J]. Science and Engineering of Composite Materials, 2018, 25(2): 273-287.

[16] KABETA W F, LEMMA H. Modeling the application of steel slag in stabilizing expansive soil[J]. Modeling Earth Systems and Environment, 2023, 9(4): 4023-4030.

[17] 刘清秉, 项伟, 张伟锋, 等. 离子土壤固化剂改性膨胀土的试验研究[J]. 岩土力学, 2009, 30(8): 2286-2290. LIU Qingbing, XIANG Wei, ZHANG Weifeng, et al. Experimental study of ionic soil stabilizer-improves expansive soil[J]. Rock and Soil Mechanics, 2009, 30(8): 2286-2290. (in Chinese)

[18] 朱锐, 王燕杰, 黄英豪, 等. 木质素纤维改良膨胀土的冻融特性及微观机理[J]. 农业工程学报, 2024, 40(2): 263-272. ZHU Rui, WANG Yanjie, HUANG Yinghao, et al. Freeze-thaw characteristics and microscopic mechanism of expansive soil improved by lignin fiber[J]. Transactions of the Chinese Society of Agricultural Engineering, 2024, 40(2): 263-272. (in Chinese)

[19] TIWARI N, SATYAM N, SHARMA M. Micro-mechanical performance evaluation of expansive soil biotreated with indigenous bacteria using MICP method[J]. Scientific Reports, 2021, 11(1): 10324.

[20] SHARMA J K, KHANDELWAL S. Performance evaluation of kota's black soil using perma-zyme[M]// Techno-Societal 2022. Cham: Springer International Publishing, 2023: 125-136.

[21] MEHMOOD M, GUO Y C, WANG L, et al. Influence of enzyme induced carbonate precipitation (EICP) on the engineering characteristics of expansive soil[J]. Arabian Journal for Science and Engineering, 2024: 1-16.

[22] HUANG J, KOGBARA R B, HARIHARAN N, et al. A state-of-the-art review of polymers used in soil stabilization[J]. Construction and Building Materials, 2021, 305: 124685.

[23] 刘景锦, 罗昊鹏, 雷华阳, 等. 碱激发地质聚合物固化软土的研究进展[J]. 硅酸盐通报, 2023, 42(2): 565-574. LIU Jingjin, LUO Haopeng, LEI Huayang, et al. Research progress on application of alkali-activated geopolymers to stabilize soft soil[J]. Bulletin of the Chinese Ceramic Society, 2023, 42(2): 565-574. (in Chinese)

[24] SHARMA A K, SIVAPULLAIAH P V. Ground granulated blast furnace slag amended fly ash as an expansive soil stabilizer[J]. Soils and Foundations, 2016, 56(2): 205-212.

[25] TAHA M M M, FENG C P, AHMED S H S. Modification of mechanical properties of expansive soil from North China by using rice husk ash[J]. Materials, 2021, 14(11): 2789.

[26] ZHA F S, LIU S Y, DU Y J, et al. Behavior of expansive soils stabilized with fly ash[J]. Natural Hazards, 2008, 47(3): 509-523.

[27] COKCA E, YAZICI V, OZAYDIN V. Stabilization of expansive clays using granulated blast furnace slag (GBFS) and GBFS-cement[J]. Geotechnical and Geological Engineering, 2009, 27(4): 489-499.

[28] PARSAEI M, VAKILI A H, SALIMI M, et al. Effect of electric arc and ladle furnace slags on the strength and swelling behavior of cement-stabilized expansive clay[J]. Bulletin of Engineering Geology and the Environment, 2021, 80(8): 6303-6320.

[29] ZOU W L, YE J B, HAN Z, et al. Effect of montmorillonite content and sodium chloride solution on the residual swelling pressure of an expansive clay[J]. Environmental Earth Sciences, 2018, 77(19): 677.

[30] 马田田, 于海文, 韦昌富, 等. 物理化学效应对膨胀土收缩特性的影响机制[J]. 岩土力学, 2024, 45(3): 697-704. MA Tiantian, YU Haiwen, WEI Changfu, et al. Mechanism of physicochemical effect on the shrinkage of expansive soil[J]. Rock and Soil Mechanics, 2024, 45(3): 697-704. (in Chinese)

[31] 黄春, 刘尚营, 张春光, 等. NH4+, 尿素和聚乙二醇对蒙脱土的抑制膨胀作用[J]. 化学学报, 2003, 61(7): 983-988. HUANG, Chun LIU Shangying ZHANG Chunguang, et al. Inhibition behavior of NH4+, urea and polyethylene glycol on swelling of montmorillonite[J]. Acta Chimica Sinica, 2003, 61(7): 983-988. (in Chinese)

[32] 钟玉健, 张晓超, 袁锐, 等. 非钙基土壤固化剂加固机理及其应用性能研究进展[J]. 材料导报, 2022, 36(14): 154-162. ZHONG Yujian, ZHANG Xiaochao, YUAN Rui, et al. Research progress in the stabilization mechanism of non-calcium-based soil stabilizer and its application performance[J]. Materials Reports, 2022, 36(14): 154-162. (in Chinese)

[33] TAHER Z J, SCALIA J I, BAREITHER C A. Comparative assessment of expansive soil stabilization by commercially available polymers[J]. Transportation Geotechnics, 2020, 24: 100387.

[34] SABERIAN M, PERERA S T A M, ZHU J S, et al. Investigating the impact of vinyl acetate-ethylene polymer on the mechanical and microstructural properties of expansive clay subgrade[J]. Road Materials and Pavement Design, 2024: 1-24.

[35] AL-ATROUSH E M. Reduction of soil swelling potential using PU polyurethane liquid foam[C]//Geo-Extreme 2021. Savannah, Georgia. Reston, VA: American Society of Civil Engineers, 2021: 190-202.

[36] CHITTOORI B C S, RAHMAN T, BURBANK M. Microbial-facilitated calcium carbonate precipitation as a shallow stabilization alternative for expansive soil treatment[J]. Geotechnics, 2021, 1(2): 558-572.

[37] OUYANG Q W, XIAO H B, LI Z Y, et al. Experimental study on the influence of microbial content on engineering characteristics of improved expansive soil[J]. Frontiers in Earth Science, 2022, 10: 863357.

[38] TIAN X W, XIAO H B, SU H, et al. Experimental study on creep and long-term strength characteristics of expansive soil improved by the MICP method[J]. Arabian Journal of Geosciences, 2024, 17(6): 202.

[39] POONI J, GIUSTOZZI F, ROBERT D, et al. Durability of enzyme stabilized expansive soil in road pavements subjected to moisture degradation[J]. Transportation Geotechnics, 2019, 21: 100255.

[40] TIWARI A, SHARMA J K, GARG V. Stabilization of expansive soil using terrazyme[M]// Lecture Notes in Civil Engineering. Singapore: Springer Singapore, 2021: 113-125.

[41] DILRUKSHI R A N, NAKASHIMA K, KAWASAKI S. Soil improvement using plant-derived urease-induced calcium carbonate precipitation[J]. Soils and Foundations, 2018, 58(4): 894-910.

[42] DONG J, LIU X B. Application of improved enzyme induced calcium carbonate precipitation (EICP) technology in surface protection of earthen sites[J]. Journal of Cultural Heritage, 2022, 54: 146-154.

[43] ALMAJED A, LEMBOYE K, ARAB M G, et al. Mitigating wind erosion of sand using biopolymer-assisted EICP technique[J]. Soils and Foundations, 2020, 60(2): 356-371.

[44] PRABHAKAR, ANNADURAI R. Synergistic effect of Polyvinyl Acetate (PVA) and Enzyme-Induced Carbonate Precipitation (EICP) on the mechanical properties of natural sands[J]. Case Studies in Construction Materials, 2024, 20: e03323.

[45] HAMZA M, NIE Z H, AZIZ M, et al. Strengthening potential of xanthan gum biopolymer in stabilizing weak subgrade soil[J]. Clean Technologies and Environmental Policy, 2022, 24(9): 2719-2738.

[46] LATIFI N, HORPIBULSUK S, MEEHAN C L, et al. Improvement of problematic soils with biopolymer—an environmentally friendly soil stabilizer[J]. Journal of Materials in Civil Engineering, 2017, 29(2): 04016204.

[47] VYDEHI K V, ALI BAIG MOGHAL A, MARIYAM RASHEED R. Shrinkage characteristics of biopolymer treated expansive soil[C]// Geo-Congress 2022. Charlotte, North Carolina. Reston, VA: American Society of Civil Engineers, 2022: 92-99.

[48] KANTESARIA N, CHANDRA P, SACHAN A. Stabilization of expansive soil using agar biopolymer[C]// IFCEE 2021. Dallas, Texas. Reston, VA: American Society of Civil Engineers, 2021: 272-281.

[49] LIU S H, DU K, WEN K J, et al. Stabilization of expansive clayey soil through hydrogel for mechanical improvements[J]. International Journal of Civil Engineering, 2023, 21(9): 1423-1431.

[50] SHIBAEV A V, MURAVLEV D A, MURAVLEVA A K, et al. pH-dependent gelation of a stiff anionic polysaccharide in the presence of metal ions[J]. Polymers, 2020, 12(4): 868.

[51] CAI G J, ZHANG T, LIU S Y, et al. Stabilization mechanism and effect evaluation of stabilized silt with lignin based on laboratory data[J]. Marine Georesources & Geotechnology, 2016, 34(4): 331-340.

下载:

下载: