Deformation characteristics of modified iron tailings under different cyclic loading modes

-

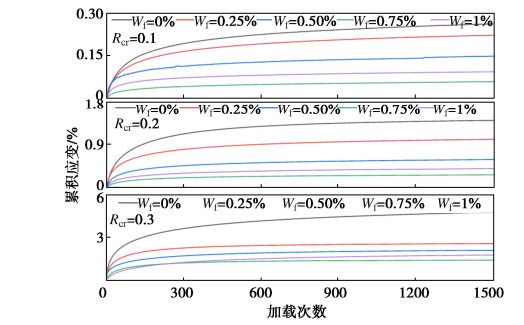

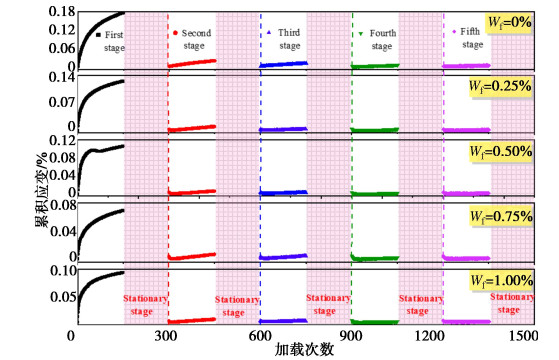

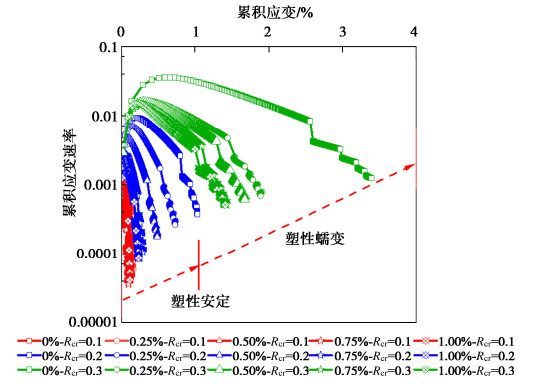

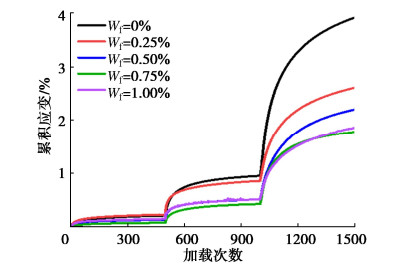

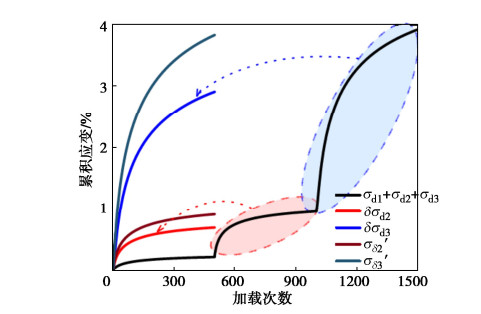

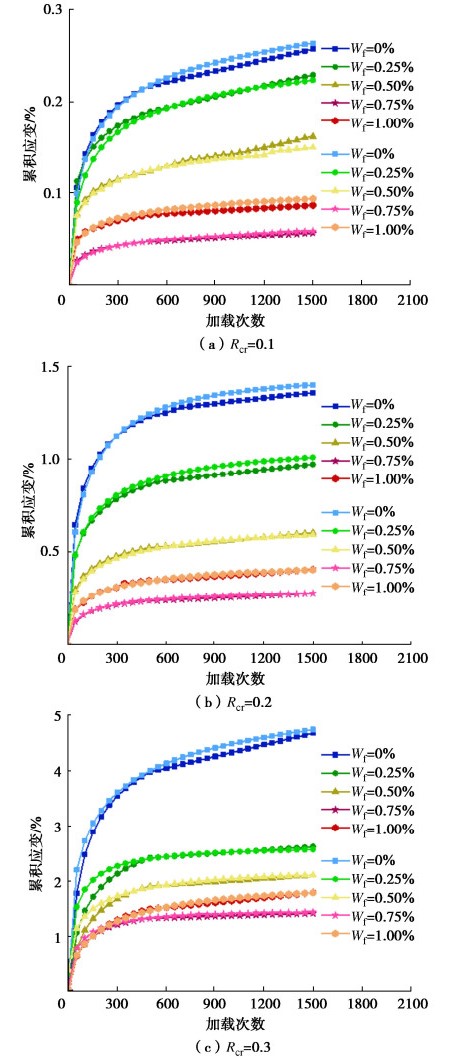

摘要: 利用聚丙烯纤维和水泥改性铁尾矿砂,并将其应用于路基工程是实现铁尾矿资源化利用的有效手段。通过动三轴试验探究了不同循环加载模式下纤维掺量、动静比和龄期对纤维水泥改性铁尾矿砂(FCIT)变形特性的影响。研究结果表明:①间歇加载和逐级加载下FCIT的变形行为在7 d龄期时处于塑性安定和塑性蠕变状态;②对比持续加载和间歇加载变形情况,发现间歇加载下FCIT的累积应变(εp)变化幅度总体上小于持续加载作用引起的εp变化幅度;③逐级加载下FCIT的累积应变被赋予倍数系数后,可较好预测持续加载下的累积应变。修正后的累积应变满足幂函数和线性函数组成的预测公式。Abstract: Using polypropylene fiber and cement to modify iron tailings, the effects of fiber content, dynamic-static ratio and curing age on the deformation characteristics of the fiber cement-modified iron tailing (FCIT) under different cyclic loading modes are explored through the dynamic triaxial tests. The research results show that: (1) The deformation behaviors of FCIT under intermittent loading and progressive loading are in the state of plastic stability and plastic creep at curing age of 7 d. (2) By comparing the deformations of continuous loading and intermittent loading, it is found that the variation range of the cumulative strain (εp) of FCIT under intermittent loading is generally smaller than that of εp caused by continuous loading. (3) Assigning a multiple factor to the cumulative strain of FCIT under progressive loading improves predictions for the cumulative strain under continuous loading. The corrected cumulative strain satisfies the prediction formula composed of power function and linear function.

-

0. 引言

伴随中国南海岛礁的建设和“一带一路”战略规划的实施,珊瑚礁砂的液化特性及地基处理方法成为工程界的热点问题之一[1-4]。碎石桩作为工程常用的一种地基抗液化处理方法,利用改善地基排水条件和振密桩周土体,使地基抗液化强度提高。然而,多次强震荷载下碎石桩长期服役的抗液化性能及淤堵性缺乏研究;同时,珊瑚礁砂地基碎石桩的抗液化有效性也尚待深入探究。

目前,国内外诸多学者利用单元试验(共振柱、动三轴等)、振动台和数值分析等手段,对珊瑚礁砂液化特性及地基处理方法开展了大量研究。如:Chen等[2]采用不排水循环三轴探讨了珊瑚礁砂的模量阻尼比特性及抗液化强度。Xiao等[3]通过动三轴试验论证了MICP法处理降低珊瑚砂液化风险的有效性。秦志光[4]基于原位勘察测试方法,分析了强夯、振冲等方法对珊瑚礁砂地基抵抗液化的加固效果;刘凯[5]联合多种研究手段,研究倾斜场地碎石桩处理地基地震液化变形规律。总之,珊瑚礁砂场地抗液化强度及处理方法有效性,尚有待深入研究,辟如:刘凯[5]分析动力离心试验碎石桩长期服役性能时,指出碎石桩渗入细粒而发生淤堵,但多次强震下超静孔压消散速率并未明显改变,二者相悖。

本文以东帝汶Tibar港口码头工程为背景,开展珊瑚礁砂碎石桩动力离心模型试验,施加序列强震荷载,利用碎石桩剖面图像观测、试验前后级配测试、超静孔压比消散速率变化等分析,探讨多次强震下碎石桩淤堵性及排水性能变化,为评判碎石桩长期服役的有效性和工程建设提供参考。

1. 动力离心试验设备与模型设计

1.1 试验设备

本次试验在中国地震局工程力学研究所振动负载1500 kg动力离心机上开展,其主机及振动台如图 1所示。该试验设备的主要技术指标:有效负载300 g·t,离心加速度100g,最大半径5.5 m,振动加速度30g,振动速度1 m/s,振动位移10 mm,振动频宽10~300 Hz,振动台台面有效尺寸为1.6 m×0.8 m,配置160 ch动态数据采集系统。试验选取柔性剪切模型箱,内尺寸1.2 m×0.5 m×0.65 m。

1.2 试验模型材料

本次试验采用Tibar港口工程原位珊瑚礁砂,原始土样颗粒级配宽,属于粗粒土,如图 2所示。动力离心试验作为一种缩尺物理试验,考虑《土工离心模型试验技术规程》(DL∕T 5102—2013)[6]的规定:“对于粗粒土,允许最大粒径应不超过1/20~1/10模型宽度,其平均粒径不超过1/250~1/60模型宽度”,借鉴以往学者们对珊瑚礁砂试验剔除2 mm以上颗粒来避免粒径效应[7],本文试验保留了2~5 mm颗粒,仅剔除 > 5 mm颗粒,既能满足《规范》的粒径效应要求,又有助于反映真实的工程土体力学行为,剔除后的试验珊瑚礁砂级配如图 2所示。

碎石桩的面积置换率、桩型等设计参数与工程原型保持一致,确定碎石桩置换率14.5%,按正三角形布设,为悬浮桩。并为避免尺寸效应影响,确定碎石桩直径为80 mm,由置换率确定桩间距为200 mm,碎石桩级配考虑其主要依赖快速排水能力实现地基发生液化风险和程度的降低,按工程原型碎石桩与场地土体渗透系数比值800作为主要控制参数进行设计,同时考虑粒径效应与碎石桩直径、原型碎石级配相似等因素,设计的碎石桩级配如图 2所示。试验模型地基和碎石桩材料的基本物理力学参数,见表 1。

表 1 试验材料基本物理力学参数Table 1. Physical properties of test materials试验材料 Gs ρmax/ (g·cm-3) ρmin/ (g·cm-3) emin emax k/ (cm·s-1) 珊瑚礁砂 2.785 1.826 1.386 0.525 1.009 5.1×10-3 碎石桩 2.370 1.754 1.446 0.248 0.580 4.443 1.3 模型设计与试验方案

试验模型设计与量测方案如图 3所示,地基土为400 mm厚珊瑚礁砂,相对密实度50%,采用砂雨法+分层压实法制备。碎石桩桩长300 mm,相对密实度70%,采用分层夯实法制备。试验模型地基内布设了一列加速度和孔压传感器,还在碎石桩表面和桩周地表布设了位移计,以监测模型沉降变化。试验所用加速度计为美国PCB传感器,孔压计为中国地震局工程力学研究所自主研制分体式DSP-Ⅱ传感器。

试验离心加速度为50g,选取LEAP波、安评地震波为输入荷载,台面实测荷载时程如图 4所示。安评地震波输入峰值分别为0.05g,0.1g,0.2g,0.3g,0.4g,0.53g等工况,LEAP输入峰值分别为0.05g,0.1g,0.2g,0.3g等工况,两种荷载交替输入。

2. 碎石桩淤堵性分析

2.1 强震荷载下地基液化分析

试验模型在7条峰值≥0.2g强震荷载下,埋深1.25 m处土体均发生了液化,即超静孔压达到了有效应力,而埋深7.5 m处超静孔压随着地震动强度增大而增大,但一直未达到该位置有效应力,未发生液化,如图 5所示。

2.2 试验后模型开挖及碎石桩剖面

试验完成后沿模型中心剖面进行了开挖,获得了5根碎石桩剖面如图 6所示。仔细观察和对比可发现,碎石桩在试验过程中保持了良好形态,桩周未包裹珊瑚礁砂细粒,仍具备良好的渗透能力。图 6给出了5根开挖后的代表性碎石桩剖面照片,可以直观看出碎石桩内颗粒分布均匀、色泽与桩周土体区分明显,由粗颗粒组成,均未出现明显细颗粒淤堵现象。

2.3 试验前后碎石桩颗粒级配对比

以试验前后碎石桩粒组变化差异,判断是否产生了淤堵,试验前后分别作了碎石桩材料筛分试验,结果如图 7所示,可以发现试验后碎石桩级配与试验前相比基本一致,表明细粒未渗入到碎石桩中,与前面碎石桩剖面观察结果一致。

2.4 超静孔压比消散速率分析

选取图 5中第1次0.2g和第6次0.53g安评地震波下埋深1.25 m和7.5 m处超静孔压比记录(如图 8所示),计算分析多次强震作用下碎石桩排水性能的变化,以超静孔压比消散速率为表征参数,其公式如下:

v=ΔruΔt。 (1) 式中:Δru为超静孔压比自峰值消散至0.1的变化量;Δt为与超静孔压比消散对应的时间变化量。

通过式(1)计算,获得0.2g和0.53g安评波下,埋深1.25 m处超静孔压比的消散速率分别为0.027 s-1,0.029 s-1;7.5 m处超静孔压比消散速率分别为0.021 s-1,0.020 s-1,可得知6次强震荷载下土层超静孔压比消散速率未发生变化,再一次证明了经历多次强震作用后,碎石桩仍能保持良好排水性能;同时,也证明了碎石桩长期服役下的良好抗液化能力。

3. 结论

(1)珊瑚礁砂碎石桩复合地基在7次≥0.2g强震荷载作用下均发生了液化,埋深1.25 m处超静孔压比均达到了1.0;7.5 m处未发生液化,但超静孔压比随着地震动强度的增大而增大。

(2)试验后开挖5根碎石桩剖面,直观观察可发现,碎石桩经历多次强震作用下仍能保持良好形态,且未明显发现细粒渗入碎石桩现象,试验前后获得碎石桩颗粒级配曲线基本一致,无明显变化。

(3)提出以超静孔压比消散速率表征地基排水能力,第1次和第6次安评波荷载下,埋深1.25 m处超静孔压比消散速率分别为0.027 s-1,0.029 s-1,埋深7.5 m处分别为0.021 s-1,0.020 s-1,表明碎石桩经历多次强震作用下仍具备良好的渗透能力,未出现淤堵现象。

-

表 1 不同加载模式下FCIT试验方案

Table 1 FCIT test schemes under different loading modes

组号 纤维掺量 动静比Rcr 围压/kPa 频率/Hz 加载模式 加载时间 A 0%,0.25%,0.50%,0.75%,1% 0.1,0.2,0.3 100 0.5 持续加载 持续加载50 min B 间歇加载 加载5 min、停振5 min共50 min C 逐级加载 依次加载三级,共50 min -

[1] SÁ T, ODA S, BALTHAR V, et al. Use of iron ore tailings and sediments on pavement structure[J]. Construction and Building Materials, 2022, 342: 128072. doi: 10.1016/j.conbuildmat.2022.128072

[2] BASTOS L, SILVA G, MENDES J, et al. Using iron ore tailings from tailing dams as road material[J]. Journal of Materials in Civil Engineering, 2016, 28: 04016102. doi: 10.1061/(ASCE)MT.1943-5533.0001613

[3] LI N, LV S, WANG W, et al. Experimental investigations on the mechanical behavior of iron tailings powder with compound admixture of cement and nano-clay[J]. Construction and Building Materials, 2020, 254: 119259. doi: 10.1016/j.conbuildmat.2020.119259

[4] 姜屏, 杨建冬, 李娜, 等. 纤维改性水泥稳定铁尾矿砂的无侧限抗压性能研究[J]. 复合材料科学与工程, 2021(8): 73-79. https://www.cnki.com.cn/Article/CJFDTOTAL-BLGF202108011.htm JIANG Ping, YANG Jiandong, LI Na, et al. Unconfined compressive properties of fiber modified cement stabilized iron tailings[J]. Composites science and engineering, 2021(8): 73-79. (In Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BLGF202108011.htm

[5] JIANG P, LV S, WANG Y, et al. Investigation on direct shear and energy dissipation characteristics of iron tailings powder reinforced by polypropylene fiber[J]. Applied Sciences, 2019, 9(23): 2076-3417.

[6] JIANG P, QIAN J, LI N. Reliability analysis of a direct shear test of modified iron tailings based on the monte carlo algorithm[J]. Advances in Civil Engineering, 2020: 1-11.

[7] XIAO H, ZHANG N, LI G, et al. Graphene-iron ore tailings-based cementitious composites with high early flexural strength[J]. Materials, 2022, 16: 327. doi: 10.3390/ma16010327

[8] HUANG D, SUN R, WEI S, et al. Research on mechanical properties of cement mortar with iron tailings[J]. Applied Mechanics and Materials, 2014, 3512: 169-172.

[9] YANG L, XU F. Experimental study on the effect of fine powder in iron tailings on the durability of ordinary dry mixed mortar[J]. Integrated Ferroelectrics, 2021, 213(1): 1-11. doi: 10.1080/10584587.2020.1728677

[10] JI X, ENYONG S, SUN Y, et al. Study on crack resistance of cement-stabilized iron tailings[J]. International Journal of Pavement Engineering, 2022: 1-14.

[11] 孟凡丽, 娄桢桢, 葛威. 长期循环荷载下卸荷粉土动力特性的试验研究[J]. 岩土力学, 2022, 43(增刊1): 383-388. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2022S1039.htm MENG Fanli, LOU Zhenzhen, GE Wei. Experimental study on dynamic characters of unloading silt under long-term cyclic loading[J]. Rock and Soil Mechanics, 2022, 43(S1): 383-388. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2022S1039.htm

[12] JIANG P, CHEN Y, LI N, et al. Cumulative deformation and damage evolution of fiber cement–modified iron tailings under cyclic load[J]. International Journal of Geomechanics, 2023, 23(4): 04023004. doi: 10.1061/IJGNAI.GMENG-8103

[13] 何绍衡, 刘志军, 夏唐代, 等. 长期循环荷载下珊瑚砂累积变形特性试验研究[J]. 岩土工程学报, 2019, 41(增刊2): 161-164. doi: 10.11779/CJGE2019S2041 HE Shaoheng, LIU Zhijun, Xia Tangdai, et al. Experimental study on cumulative deformation characteristics of coral sand under long-term cyclic loading[J]. Chinese Journal of Geotechnical Engineering., 2019, 41(S2): 161-164. (in Chinese) doi: 10.11779/CJGE2019S2041

[14] CHEN C, ZHOU Z, KONG L-W, et al. Undrained dynamic behaviour of peaty organic soil under long-term cyclic loading, Part I: Experimental investigation[J]. Soil Dynamics and Earthquake Engineering, 2018, 107: 279-291. doi: 10.1016/j.soildyn.2018.01.012

[15] YAFENG L, NIE R-S, YUE Z, et al. Dynamic behaviors of fine-grained subgrade soil under single-stage and multi-stage intermittent cyclic loading: Permanent deformation and its prediction model[J]. Soil Dynamics and Earthquake Engineering, 2021, 142: 106548. doi: 10.1016/j.soildyn.2020.106548

[16] NIE R, MEI H, LENG W, et al. Characterization of permanent deformation of fine-grained subgrade soil under intermittent loading[J]. Soil Dynamics and Earthquake Engineering, 2020, 139: 106395. doi: 10.1016/j.soildyn.2020.106395

[17] LI Y F, NIE R S, LI Y J, et al. Cumulative plastic deformation of subgrade fine-grained soil under intermittent cyclic loading and its prediction model[J]. Rock and Soil Mechanics, 2021, 42: 1065-1077.

[18] 聂如松, 李亚峰, 冷伍明, 等. 列车间歇荷载作用下路基细粒土填料的塑性变形行为及临界动应力研究[J]. 岩石力学与工程学报, 2021, 40(4): 828-841. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX202104016.htm NIE Rusong, LI Yafeng, LENG Wuming, et al. Plastic deformation and critical dynamic stress of fine-grained soils under intermittent loading of trains[J]. Chinese Journal of Rock Mechanics and Engineering, 2021, 40(4): 828-841. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX202104016.htm

[19] 李亚峰, 聂如松, 冷伍明, 等. 间歇性循环荷载作用下细粒土的变形特性[J]. 浙江大学学报(工学版), 2020, 54(11): 2109-2119. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDZC202011006.htm LI Yafeng, NIE Rusong, LENG Wuming, et al. Deformation characteristics of fine-grained soil under cyclic dynamic loading with intermittence[J]. Journal of Zhejiang University (Engineering Science), 2020, 54(11): 2109-2119. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDZC202011006.htm

[20] 黄娟, 彭立敏, 袁铁映, 等. 分级加载条件下泥炭质土滞回曲线演化规律试验研究[J]. 中南大学学报(自然科学版), 2018, 49(7): 1753-1759. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201807023.htm HUANG Juan, PENG Limin, YUAN Tieying, et al. Experimental study on evolution law of hysteretic curves of peaty soil under stepped axial cyclic loading[J]. Journal of Central South University (Science and Technology), 2018, 49(7): 1753-1759. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201807023.htm

[21] ASEFZADEH A, HASHEMIAN L, BAYAT A. Characterization of permanent deformation behavior of silty sand subgrade soil under repeated load triaxial tests[J]. Transportation Research Record, 2017, 2641(1): 103-110. doi: 10.3141/2641-13

[22] GU F, ZHANG Y, LUO X, et al. Characterization and prediction of permanent deformation properties of unbound granular materials for Pavement ME Design[J]. Construction and Building Materials, 2017, 155: 584-592. doi: 10.1016/j.conbuildmat.2017.08.116

[23] XIAO Y, ZHENG K, CHEN L, et al. Shakedown analysis of cyclic plastic deformation characteristics of unbound granular materials under moving wheel loads[J]. Construction and Building Materials, 2018, 167: 457-472. doi: 10.1016/j.conbuildmat.2018.02.064

[24] CAI Y, TANG X, LIN L, et al. Strain rate response of damage accumulation of marble under fatigue loading[J]. Chinese Journal of Geotechnical Engineering, 2020, 42: 827-836.

[25] WANG K, ZHUANG Y. Characterizing the permanent deformation Response-Behavior of subgrade material under cyclic loading based on the shakedown theory[J]. Construction and Building Materials, 2021, 311: 125325. doi: 10.1016/j.conbuildmat.2021.125325

[26] 梅慧浩, 聂如松, 冷伍明, 等. 考虑时间间歇效应的粉土永久变形特性单级和分级加载动三轴试验研究[J]. 铁道学报, 2021, 43(12): 94-104. https://www.cnki.com.cn/Article/CJFDTOTAL-TDXB202112012.htm MEI Huihao, NIE Rusong, LENG Wuming, et al. Characterisation of permanent deformation behaviour of silt by using both single-stage and multi-stage repeated load triaxial tests considering time intermittent effect[J]. Journal of the China Railway Society, 2021, 43(12): 94-104. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-TDXB202112012.htm

-

期刊类型引用(5)

1. 熊金鑫. 长春地铁车站基坑工程地表变形沉降特性分析. 工程机械与维修. 2025(01): 148-150 .  百度学术

百度学术

2. 王铁. 桩-锚支护深基坑开挖诱发地表沉降分析. 中国建筑金属结构. 2025(05): 25-27 .  百度学术

百度学术

3. 刘禹,刘性锋,李世堂,周静. 考虑多因素的深埋管线施工对临近地铁影响分析——以龙泉驿区玉竹路为例. 科技和产业. 2024(18): 327-332 .  百度学术

百度学术

4. 蔡辉翔. 邻近地铁隧道的深基坑开挖技术研究. 价值工程. 2024(32): 88-91 .  百度学术

百度学术

5. 丰土根,王湛铭,张箭,彭朋,孙津津,王威,李明东. 基坑开挖卸荷对侧方隧道的影响研究——以南京市某地铁车站基坑开挖为例. 东华理工大学学报(自然科学版). 2024(05): 482-494 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: