Intelligent geotechnical engineering

-

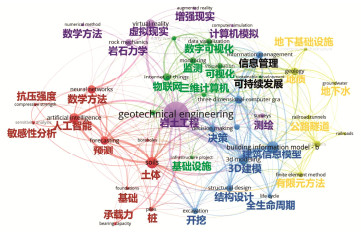

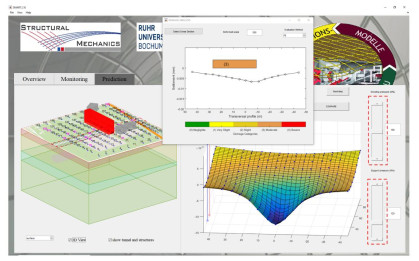

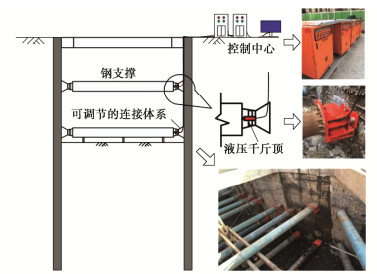

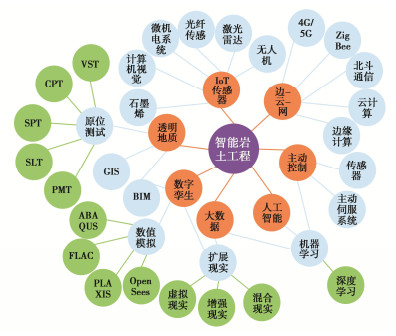

摘要: 以物联网、现代通讯、大数据、人工智能等技术为核心的第四次工业革命成为了众多研究领域智能化升级的平台,新时代条件下传统岩土工程研究遇到了前所未有的机遇和挑战,岩土工程与最新的信息技术、计算机科学技术相互融合,如建筑信息模型、物联网、人工智能、深度学习、增强现实等可实现岩土工程的智能化转型。研究初步构建了“智能岩土工程”的知识图谱,探索了相应的实现路径,阐述了基于新技术的三维地质建模–物联网–深度学习–扩展现实的岩土工程智能化转型方法;介绍了建筑信息模型(BIM)与地理信息系统(GIS)一体化的三维地质建模、“端–边–云–网”的技术架构、以主动伺服加载系统为代表的岩土工程(深基坑工程)风险主动控制系统;阐明了物联网传感器技术在岩土工程领域的应用情况、虚拟现实与增强现实技术在岩土工程领域的应用现状;分析了人工智能(深度学习)在岩土工程风险预测预警方面的关键作用;构建了未来智能岩土工程的知识图谱,为拟从事智能岩土工程相关的研究人员提供借鉴。Abstract: The fourth industrial revolution based on the core technologies of Internet of Things (IoT), modern communication, big data and artificial intelligence (AI) is an upgrading platform for many different research fields. The traditional geotechnical engineering has great opportunities and grand challenges in this new era. Integration of the geotechnical engineering, innovative information technology and computer science technology such as building information modelling (BIM), IoT, AI, deep learning and argument reality can be used to realize intelligent transformation of the traditional geotechnical engineering. The knowledge mapping of the intelligent geotechnical engineering is preliminarily established, and the relevant realization paths are investigated. The transformation method for the intelligent geotechnical engineering "3D geological modelling-IoT-deep learning-extended reality" based on the innovative technologies is depicted. 3D geological modelling using the fusion of BIM and the geographic information system, the technological frame of "end-edge-cloud-network" and the active risk control for geotechnical engineering (deep excavation engineering) based on the active servo-loading system are introduced. The application status of the IoT sensoring technology visual reality and argument reality in the geotechnical engineering is introduced. The key role of AI (deep learning) in the geotechnical engineering for monitoring and early warning is analyzed. The knowledge mapping of future development of the intelligent geotechnical engineering is proposed, providing advice and guidance for the relevant researchers in the geotechnical engineering.

-

0. 引言

中国城市轨道交通近年来迅猛发展,已经成为市政基础设施的主要组成之一,随之而来的深基坑工程由于建设条件越来越复杂,常常出现自身安全性与周边环境稳定性的破坏。兰州市东西狭长而南北窄的带状分布严重阻碍了市区交通的运输[1],为此规划的地铁线网在施工中碰到了西北地区特殊的富水红砂岩层,其工程性质差别很大,压实胶结作用差,揭露后极易发生风化,未扰动前力学性质较好,遇水扰动后强度快速衰退,崩解成流塑形的散沙,从而引发诸多地质工程问题[2-5],而地铁深基坑支护结构的设计目前仍处在施工探索和实践的阶段。兰州地铁各车站基坑的红砂岩地层岩性差异非常大,若不对红砂岩分类并针对性地进行支护结构设计和地下水处理,将导致基坑被水浸泡、坑壁涌水涌砂等一系列工程问题。定西路站基坑内的红砂岩地层遇水具有典型的崩解特性,与之相应的基坑支护和地下水治理方案的研究刻不容缓。

国内外学者对深基坑支护结构的力学与变形特性已经做了大量的工作[6-10],但都没有针对兰州地区特殊红砂岩地层的深入研究。本文依托定西路站车站深基坑工程,对开挖过程中的监测数据和Midas GTS的数值模拟结果对比分析,验证支护方案设计的合理性,研究结果可为类似红砂岩分布地区基坑支护结构设计提供技术支持。

1. 工程概况

1.1 车站概况

定西路车站轴线近南北向分布,车站总长185 m,标准段宽约23.3 m,底板埋深24.33~24.73 m,主体基坑施工方式为明挖法。车站两侧密集的建筑物加大了围护结构的受力,对基坑支护产生了不利影响。

1.2 地质及水文条件

场地45.0 m勘探深度范围内各地层的岩性及埋藏条件如表 1。车站地下水为潜水,卵石层为主要含水层,埋深为5.0~11.0 m,其下第三系粉砂岩成岩作用差,岩层内存在与卵石层相通的裂隙水。

表 1 岩土参数Table 1. Geotechnical parameters地层 层厚/m 重度/(kN·m-3) 黏聚力/kPa 内摩擦角/(°) 渗透系数/(m·d-1) 黄土状土 0.7~10.2 18.3 17 20 5.0~8.0 卵石 5.0~11.0 21.0 0 40 25.8~35.3 强风化砂岩 5.7~10.8 20.7 30 33 2.1~2.9 中风化砂岩 未穿透 21.3 40 38 0.5~1.0 1.3 支护结构方案

车站场地砂岩层渗透性较小、流通性差,降水周期短会导致层间滞水,坑壁渗水将引发强风化粉砂岩崩解,给基坑侧壁安全带来极大的风险,场地特有的水文地质条件和岩土工程问题要求车站基坑的支护结构兼具支承及止水能力。

车站结构形式为地下二层单柱双跨箱型框架结构,综合考虑经济性和安全性,该站基坑采用咬合桩加内支撑支护。桩墙由Φ1000@1400 mm的C35钢筋混凝土钻孔灌注桩与Φ800@1400 mm的C15素混凝土旋喷桩咬合而成,咬合深度为200 mm,桩长24.118 m。标准段沿竖向布置三道内支撑,钢筋混凝土撑水平间距约6 m,钢管撑水平间距为3 m,支护结构如图 1所示。

2. 现场测试与分析

2.1 监测方案

根据《城市轨道交通工程监测技术规范》(GB50911—2013)制定监测方案,各监测项目及控制值如表 2,监测点平面布置如图 2。

表 2 基坑监测项目及控制值Table 2. Foundation pit monitoring items and control values监测项目 累计绝对值/mm 累计开挖深度/% 变化速率/(m·d-1) 周边地表沉降 30 0.20 3 建筑物沉降 30 0.20 3 支撑轴力 轴力设计值 2.2 基坑周边地表沉降分析

地表沉降监测点DB10-1、DB10-2和DB10-3随时间的变化关系曲线如图 3。由图 3可得,各监测点的地表累计沉降量随着基坑开挖深度增大上下波动,但总体上都在增大。开挖初期,最大沉降的位置离基坑边缘较近,随着基坑开挖深度增加,距离基坑边缘较远的DB10-3沉降值更大,说明此时坑外土体向内倾斜对地表沉降产生的影响比内支撑的抑制作用大。

随着施工的进行,基坑周边地表起伏变化。基坑开挖是卸荷过程,开挖初期内支撑未支护时,地表沉降。6月17日左右,第一道钢支撑施工完成,支护桩后的土体受到朝基坑外的挤压,地表出现较小的隆起现象。随着开挖深度增大,地表再次沉降,7月15日,第二道钢支撑施工完成,地表再次隆起。DB10-3的最大沉降值为12.28 mm,远小于控制值30 mm,表明基坑支护安全有效,基坑开挖对周边地表的影响在可控范围内。

2.3 基坑周边建筑物沉降分析

某栋楼四角监测点CJ-12、CJ-13、CJ-14和CJ-15的累计沉降值随时间的变化关系曲线如图 4。可知随着基坑开挖建筑物整体上在沉降,5月13日第一道支撑施工完成,建筑物向上隆起,6月17日第二道支撑施工后,建筑物整体发生微小的隆起变形,之后各监测点均表现为沉降,7月15日第三道支撑完成后,建筑物的沉降逐渐趋于平稳。

距离基坑边缘较近的监测点CJ-12和CJ-13,变化曲线基本一致,较远的CJ-14和CJ-15的变化趋势相似,前者的沉降值整体上大于后者,可见基坑开挖对周边建筑物产生的影响随着距离的增加而减小。各测点在监测期得最大沉降量分别为6.29,5.42,4.73,3.72 mm,远小于控制值30 mm,表明内支撑可有效减小基坑周边建筑物沉降。

2.4 内支撑轴力分析

基坑原设计为三道钢支撑,轴力设计值分为721,1847,1616 kN。监测点ZL07的三道内支撑轴力随时间的变化曲线如图 5。随着基坑开挖,三道支撑的轴力变化先上下起伏,在开挖完成后逐渐趋于稳定,可能与开挖深度不相等、内支撑预应力损失、间歇性施工等原因有关。5月13日第一道钢筋混凝土支撑施工完成,由于混凝土的收缩,使之受到943 kN的初始压应力。6月17日第二道支撑完成后,钢筋混凝土支撑的轴力明显下降,这是因为第二道支撑分担了基坑内土层卸荷产生的压力。7月15日第三道支撑完成,第一、二道支撑的轴力明显减小,之后三道支撑承担的围护桩后的土压力随基坑开挖深度增加越来越大,轴力也逐渐增大。

第一道支撑的轴力监测值始终大于设计值,其中最大值为1691 kN,超过设计值的135%,故实际施工中用钢筋混凝土支撑代替了钢支撑。第二道支撑轴力最大值为1367 kN,轴力利用率较高。第三道支撑最大值为598 kN,轴力最大利用率为37%,设计偏保守。开挖过程未出现支撑破坏及基坑变形过大等现象,表明基坑支撑设计还有很大的优化空间,可进一步加强安全与经济的统一性。

3. 数值模拟及对比分析

3.1 模型及边界条件

选取14~20轴之间的基坑标准段建立Midas GTS有限元模型,模型尺寸为100 m×48 m×60 m,网格划分如图 6。将模型涉及的土层简化为4层,岩土体采用修正莫尔-库仑(MMC)模型,支护结构采用弹性本构模型。根据基坑开挖步骤定义施工阶段如表 3。

表 3 开挖工况Table 3. Excavation conditions工况 时间 施工状态 1 开始开挖—2018-05-13 开挖深度2.4 m,第一道钢筋混凝土支撑施工完成 2 2018-05-13—2018-06-17 开挖深度9.7 m,第一道钢支撑施工完成 3 2018-06-17—2018-07-15 开挖深度15.75 m,第二道钢支撑施工完成 4 2018-07-15—2018-07-29 开挖深度20.22 m,防水垫层已浇筑,底板钢筋施工 3.2 基坑周边地表沉降对比分析

对比地表沉降监测点DB10-1的模拟值与监测值,如图 7所示。可知模拟值整体上小于实测值,这是由于模拟计算的条件比较理想,简化了土层,假设开挖在降水完成后进行,且未考虑基坑周围可能出现临时堆载等不确定因素,但两条曲线总体的变化趋势一致,说明模拟计算的各参数选取较为合理。实测最大值为-2.17 mm,模拟最大值为-1.5 mm,均远小于控制值-30 mm,由于咬合桩加内支撑的支护结构刚度大,且同一时间的开挖段较短,对支护墙后的红砂岩地层扰动小,因此基坑周边地表累计沉降值远小于控制值。

3.3 内支撑轴力对比分析

选取建模区域内的支撑轴力监测点ZL07,对比第一道支撑的模拟数据和监测数据如图 8。由图可知,两条曲线的变化趋势基本一致,各工况下轴力的模拟值都小于监测值,可能与建模条件较为理想、忽略了实际施工中基坑周边施工机具堆载等情况有关。由于钢筋混凝土支撑的刚度大,整个开挖过程支撑和基坑都未出现过大的变形。

4. 结论

(1)基坑开挖初期距离基坑边缘较近的位置地表沉降量更大,随着开挖深度增加较远位置的沉降量更大;基坑周边地表竖向位移随施工过程呈现沉降-隆起-沉降的起伏变化;内支撑可有效减小基坑周边建筑物沉降。

(2)第一道支撑的轴力始终大于设计值,第二道的轴力利用率高,第三道设计偏保守,支护结构设计可进一步优化,做到经济性和安全性相统一。

(3)各施工监测项目结果与数值模拟结果随时间的变化趋势一致,表明有限元软件可预测深基坑工程可能存在问题并优化支护方案。

(4)开挖过程未出现支撑破坏及基坑变形过大等现象,说明针对定西路车站红砂岩地层岩性条件下的深基坑支护结构合理有效,设计思路对后续兰州地铁同类型红砂岩基坑支护有指导作用。

-

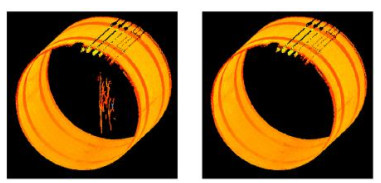

图 3 隧道图像测量设备[21]

Figure 3. Measurement devices for tunnel topography

图 4 沿激光扫描仪视线拍摄的地面混合像素横截面[24]

Figure 4. Example of automatically-detected mixed pixels in a single scan station

图 5 激光扫描仪获取的隧道点云图与处理方法[28]

Figure 5. Obtained point cloud of a tunnel

-

[1] 赵艳莉. 基于计算机三维地质模型的岩土工程设计与可视分析——评《岩土工程勘察与设计》[J]. 岩土工程学报, 2019, 41(7): 1381. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201907028.htm ZHAO Yan-li. Based on the design and visual analysis of geotechnical engineering based on computer three-dimensional geological model[J]. Journal of Geotechnical Engineering, 2019, 41(7): 1381. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201907028.htm

[2] 谭顺辉. 隧道掘进机多功能化及智能化的发展与推广[J]. 隧道建设, 2020, 40(9): 1243–1250. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD202009001.htm TAN Shun-hui. Development and application of multi-functional and intelligent tunnel boring machine[J]. Tunnel Construction, 2020, 40(9): 1243–1250. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD202009001.htm

[3] 陈祖煜, 赵宇飞, 邹斌, 等. 填筑碾压施工无人驾驶技术的研究与应用[J]. 水利水电技术, 2019, 50(8): 1–7. https://www.cnki.com.cn/Article/CJFDTOTAL-SJWJ201908001.htm CHEN Zu-yu, ZHAO Yu-fei, ZOU Bin, et al. Research and application of drive technology of dam filling rolling construction[J]. Water Resources & Hydropower Technology, 2019, 50(8): 1–7. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-SJWJ201908001.htm

[4] 熊自明, 卢浩, 王明洋, 等. 我国大型岩土工程施工安全风险管理研究进展[J]. 岩土力学, 2018, 39(10): 3703–3716. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201810028.htm XIONG Zi-ming, LU Hao, WANG Ming-yang, et al. Research progress on safety risk management for large scale geotechnical engineering construction in China[J]. Rock and Soil Mechanics, 2018, 39(10): 3703–3716. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201810028.htm

[5] 戴妙林, 屈佳乐, 刘晓青, 等. 基于GA-BP算法的岩质边坡稳定性和加固效应预测模型及其应用研究[J]. 水利水电技术, 2018, 49(5): 165–171. https://www.cnki.com.cn/Article/CJFDTOTAL-SJWJ201805024.htm DAI Miao-lin, QU Jia-le, LIU Xiao-qing, et al. Study on GA-BP hybrid algorithm-based prediction model and its application to rock slope stability and reinforcement effect[J]. Water Resources and Hydropower Engineering, 2018, 49(5): 165–171. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-SJWJ201805024.htm

[6] ONSEL I E, CHANG O, MYSIOREK J, et al. Applications of mixed and virtual reality techniques in site characterization[C]// 26th Vancouver Geotechnical Society Symp. Vancouver, 2019.

[7] WANG R X, WANG R, FU P C, et al. Portable interactive visualization of large-scale simulations in geotechnical engineering using Unity3D[J]. Advances in Engineering Software, 2020, 148: 102838. doi: 10.1016/j.advengsoft.2020.102838

[8] VAN ECK N J, WALTMAN L, VOSviewer Manual[M]. Leiden: Univeristeit Leiden, 2011.

[9] 韩同春, 林博文, 何露, 等. 基于GIS与数值模拟软件耦合的三维边坡建模方法及其稳定性研究[J]. 岩土力学, 2019, 40(7): 2855–2865. doi: 10.16285/j.rsm.2018.0439 HAN Tong-chun, LIN Bo-wen, HE Lu, et al. Three-dimensional slope modelling method and its stability based on coupled GIS and numerical simulation software[J]. Rock and Soil Mechanics, 2019, 40(7): 2855–2865. (in Chinese) doi: 10.16285/j.rsm.2018.0439

[10] VALERIA N, ROBERTA V, VITTORIA C A. A new frontier of BIM process: geotechnical BIM[C]// Proceedings of the Ⅻ European Conference on Soil Mechanics and Geotechnical Engineering, Icelandic Geotechnical Society. Reykjavik, 2019.

[11] ZOU Y, KIVINIEMI A, JONES S W. A review of risk management through BIM and BIM-related technologies[J]. Safety Science, 2017, 97: 88–98. doi: 10.1016/j.ssci.2015.12.027

[12] FABOZZI S, BIANCARDO S A, VEROPALUMBO R, et al. I-BIM based approach for geotechnical and numerical modelling of a conventional tunnel excavation[J]. Tunnelling and Underground Space Technology, 2021, 108: 103723. doi: 10.1016/j.tust.2020.103723

[13] HONG C Y, ZHANG Y F, ZHANG M X, et al. Application of FBG sensors for geotechnical health monitoring, a review of sensor design, implementation methods and packaging techniques[J]. Sensors and Actuators A: Physical, 2016, 244: 184–197. doi: 10.1016/j.sna.2016.04.033

[14] ZHANG C C, SHI B, ZHU H H, et al. Toward distributed fiber-optic sensing of subsurface deformation: a theoretical quantification of ground-borehole-cable interaction[J]. Journal of Geophysical Research: Solid Earth, 2020, 125(3): e2019JB018878.

[15] ZHANG C C, ZHU H H, CHEN D D, et al. Feasibility study of anchored fiber-optic strain-sensing arrays for monitoring soil deformation beneath model foundation[J]. Geotechnical Testing Journal, 2019, 42(4): 20170321. doi: 10.1520/GTJ20170321

[16] SHI B, ZHANG D, HONGHU Z, et al. DFOS Applications to Geo-Engineering Monitoring[J]. Photonic Sensors, 2021, 11(2): 158–186. doi: 10.1007/s13320-021-0620-y

[17] CMIELEWSKI B. Use of low-cost MEMS technology in early warning system against landslide threats[J]. Acta Geodynamica et Geomaterialia, 2013: 485–490. doi: 10.13168/AGG.2013.0049

[18] BENNETT V, ABDOUN T, O'MEARA K, et al. Wireless MEMS-based in-place inclinometer-accelerometer array for real-time geotechnical instrumentation[C]//Engineering Geology and Geological Engineering for Sustainable Use of the Earth's Resources, Urbanization and Infrastructure Protection from Geohazards. Springer, 2018.

[19] KIM J, KWON S, PARK S, et al. A MEMS-based commutation module with vibration sensor for wireless sensor network-based tunnel-blasting monitoring[J]. KSCE Journal of Civil Engineering, 2013, 17(7): 1644–1653. doi: 10.1007/s12205-013-0108-4

[20] XU C Y, CHEN J W, ZHU H C, et al. Design and laboratory testing of a MEMS accelerometer array for subsidence monitoring[J]. Review of Scientific Instruments, 2018, 89(8): 085103. doi: 10.1063/1.5036666

[21] GAO Z R, LI F J, LIU Y, et al. Tunnel contour detection during construction based on digital image correlation[J]. Optics and Lasers in Engineering, 2020, 126: 105879. doi: 10.1016/j.optlaseng.2019.105879

[22] SALOMA UY E E. Image processing for geotechnical laboratory measurements[J]. International Journal of Geomate, 2016, 10(22): 1964–1970.

[23] STANIER S A, BLABER J, TAKE W A, et al. Improved image-based deformation measurement for geotechnical applications[J]. Canadian Geotechnical Journal, 2016, 53(5): 727–739. doi: 10.1139/cgj-2015-0253

[24] MILENKOVIĆ M, PFEIFER N, GLIRA P. Applying terrestrial laser scanning for soil surface roughness assessment[J]. Remote Sensing, 2015, 7(2): 2007–2045. doi: 10.3390/rs70202007

[25] MAZZANTI P. Displacement monitoring by terrestrial SAR interferometry for geotechnical purposes[J]. Geotechnical News, 2011, 29(2): 25.

[26] XU H, LI H B, YANG X G, et al. Integration of terrestrial laser scanning and NURBS modeling for the deformation monitoring of an earth-rock dam[J]. Sensors, 2018, 19(1): 22. doi: 10.3390/s19010022

[27] OSKOUIE P, BECERIK-GERBER B, SOIBELMAN L. Automated measurement of highway retaining wall displacements using terrestrial laser scanners[J]. Automation in Construction, 2016, 65: 86–101. doi: 10.1016/j.autcon.2015.12.023

[28] XIE X Y, LU X Z. Development of a 3D modeling algorithm for tunnel deformation monitoring based on terrestrial laser scanning[J]. Underground Space, 2017, 2(1): 16–29. doi: 10.1016/j.undsp.2017.02.001

[29] LI Z H, FANG L Q, SUN X K, et al. 5G IoT-based geohazard monitoring and early warning system and its application[J]. EURASIP Journal on Wireless Communications and Networking, 2021: 160.

[30] HUDSON T S, BAIRD A F, KENDALL J M, et al. Distributed Acoustic Sensing (DAS) for natural microseismicity studies: a case study from Antarctica[J]. Journal of Geophysical Research: Solid Earth, 2021, 126(7): e2020JB021493.

[31] 江月新, 黄云龙, 余建军. 基于WiFi通信的矿井监测无线传感器网络研究[J]. 煤炭技术, 2017, 36(6): 278–280. https://www.cnki.com.cn/Article/CJFDTOTAL-MTJS201706106.htm JIANG Yue-xin, HUANG Yun-long, YU Jian-jun. Research on mine monitoring wireless sensor network based on WiFi communication[J]. Coal Technology, 2017, 36(6): 278–280. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTJS201706106.htm

[32] DONG W K, LI W G, SUN Z H, et al. Intrinsic graphene/cement-based sensors with piezoresistivity and superhydrophobicity capacities for smart concrete infrastructure[J]. Automation in Construction, 2022, 133: 103983. doi: 10.1016/j.autcon.2021.103983

[33] DAI Y Y, ZHANG K, MAHARJAN S, et al. Edge intelligence for energy-efficient computation offloading and resource allocation in 5G beyond[J]. IEEE Transactions on Vehicular Technology, 2020, 69(10): 12175–12186. doi: 10.1109/TVT.2020.3013990

[34] ARMAGHANI D J, AZIZI A. Empirical, statistical, and intelligent techniques for TBM performance predictionp[J]. Applications of Artificial Intelligence in Tunnelling and Underground Space Technology, Springer, 2021: 17–32.

[35] DING Z, JIN J K, HAN T C. Analysis of the zoning excavation monitoring data of a narrow and deep foundation pit in a soft soil area[J]. Journal of Geophysics and Engineering, 2018, 15(4): 1231–1241. doi: 10.1088/1742-2140/aaadd2

[36] EID A, HESTER J G D, TENTZERIS M M. 5G as a wireless power grid[J]. Scientific Reports, 2021, 11: 636. doi: 10.1038/s41598-020-79500-x

[37] REN J, ZHANG D Y, HE S W, et al. A survey on end-edge-cloud orchestrated network computing paradigms: transparent computing, mobile edge computing, fog computing, and cloudlet[J]. ACM Computing Surveys, 2020, 52(6): 125.

[38] RAWLINGS C. Geotechnical finite element analysis-a practical guide[C]// Proceedings of the Institution of Civil Engineers-Civil Engineering, 2017.

[39] ZHANG W G, ZHANG R H, WU C Z, et al. State-of-the-art review of soft computing applications in underground excavations[J]. Geoscience Frontiers, 2020, 11(4): 1095–1106.

[40] JAFARI M. System identification of a soil tunnel based on a hybrid artificial neural network–numerical model approach[J]. Iranian Journal of Science and Technology, Transactions of Civil Engineering, 2020, 44(3): 889–899.

[41] HASANPOUR R, ROSTAMI J, SCHMITT J, et al. Prediction of TBM jamming risk in squeezing grounds using Bayesian and artificial neural networks[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2020, 12(1): 21–31.

[42] CHEN R P, ZHANG P, KANG X, et al. Prediction of maximum surface settlement caused by earth pressure balance (EPB) shield tunneling with ANN methods[J]. Soils and Foundations, 2019, 59(2): 284–295.

[43] CAO B T, OBEL M, FREITAG S, et al. Artificial neural network surrogate modelling for real-time predictions and control of building damage during mechanised tunnelling[J]. Advances in Engineering Software, 2020, 149: 102869.

[44] QIU H, FANG W, BAO H, et al. A feasibility study of virtual reality technology in guidance design of underground space[C]// International Conference on Applied Human Factors and Ergonomics. Springer, 2021.

[45] CHI H L, KANG S C, WANG X Y. Research trends and opportunities of augmented reality applications in architecture, engineering, and construction[J]. Automation in Construction, 2013, 33: 116–122.

[46] BERTAM J, MOSKALIAK J. Virtual reality training: making construction work safer[J]. Computers in Human Behavior, 2015, 43: 284–292.

[47] XU J Q, MOREU F. A review of augmented reality applications in civil infrastructure during the 4th industrial revolution[J]. Frontiers in Built Environment, 2021, 7: 640732.

[48] HANSEN L H, FLECK P, STRANNER M, et al. Augmented reality for subsurface utility engineering, revisited[J]. IEEE Transactions on Visualization and Computer Graphics, 2021, 27(11): 4119–4128.

[49] 唐德琪, 俞峰, 黄祥国, 等. 开挖诱发坑内既有基桩附加内力的模型试验[J]. 浙江大学学报(工学版), 2019, 53(8): 1457–1466. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDZC201908004.htm TANG De-qi, YU Feng, HUANG Xiang-guo, et al. Chamber tests for investigating additional internal forces in existing foundation piles induced by excavation[J]. Journal of Zhejiang University (Engineering Science), 2019, 53(8): 1457–1466. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDZC201908004.htm

[50] LI M G, DEMEIJER O, CHEN J J. Effectiveness of servo struts in controlling excavation-induced wall deflection and ground settlement[J]. Acta Geotechnica, 2020, 15(9): 2575–2590.

[51] 赵自强. 深基坑自动伺服系统应用的变形控制分析[C]// 第十五届全国工程物探与岩土工程测试学术大会. 厦门, 2017. ZHAO Zi-qiang. Deformation control analysis of automatic servo system application in deep foundation pit[C]// The 15th National Engineering Property Exploration and Geotechnical Engineering Test Academic Conference. Xiamen, 2017. (in Chinese)

[52] CHEN B G, YAN T F, SONG D B, et al. Experimental investigations on a deep excavation support system with adjustable strut length[J]. Tunnelling and Underground Space Technology, 2021, 115: 104046.

下载:

下载: