Prediction model for TBM disc cutter wear based on dense core theory

-

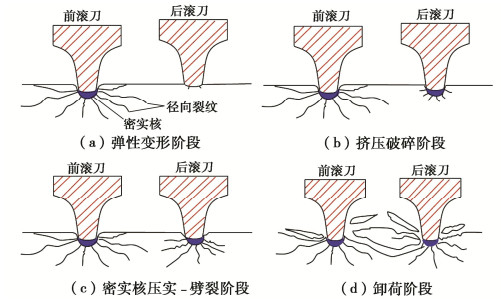

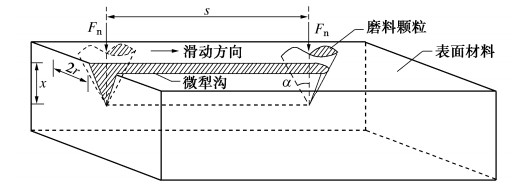

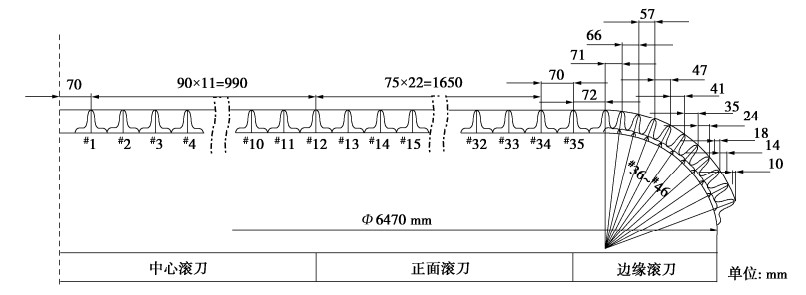

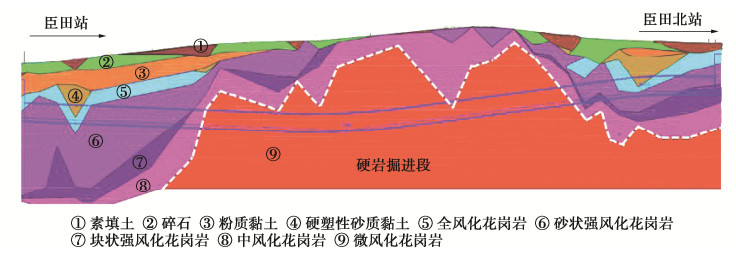

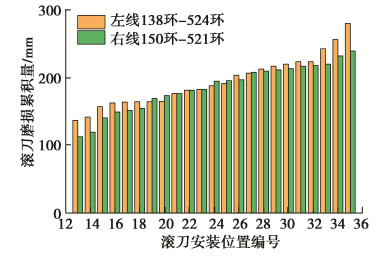

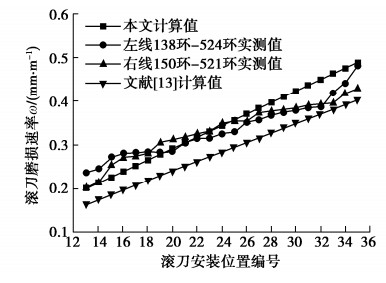

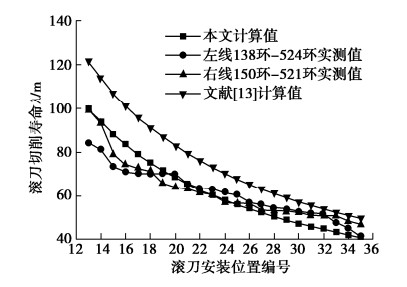

摘要: CCS(Constant Cross Section)盘形滚刀磨损是影响硬岩隧道掘进工作效率和成本预算的关键问题。根据CCS型滚刀的工作特点和岩石切割破碎原理,分析研究滚刀破碎岩石的复杂应力状态,建立了考虑密实核效应的滚刀破岩机理。通过推导密实核长度的理论解析式,获得了基于塑性去除磨粒磨损机制的滚刀磨损量与法向荷载之间的数学关系式,进而提出了滚刀磨损速率及切削寿命预测模型。基于此,分析计算了深圳地铁12号线某区间共757环的正面滚刀实测磨损数据,发现预测值与实测值的相对差异率值均小于10%,验证了预测模型的有效性。此外,通过与现有滚刀磨损预测模型对比分析,结果表明本文提出的预测模型计算结果更接近于现场实测值,说明了滚刀磨损速率和切削寿命指标可作为评价滚刀磨损特性的可靠指标,为TBM工程现场刀具更换方案设计提供更为合理可行的理论依据。Abstract: The CCS (constant cross section) type disc cutter wear is an inevitably crucial puzzle that affects the construction efficiency and cost budgeting of hard rock excavation. In this paper, according to the working characteristics of the CCS type disc cutter and the theory of rock squeezing and cutting, the complex stress state of rock-breaking by the cutter is analyzed and the mechanism of disc cutter rock-breaking considering the dense core effect is established. By deducing theoretical analytical expressions of dense core length, the mathematical relationship between cutter wear amount and normal force based on the principle of plastic removal abrasiveness is obtained, then the prediction models for wear rate and the cutting life of a disc cutter are proposed. Based on this context, by analyzing and calculating the measured wear data of the front disc cutter of a total of 757 rings in a section of Metro Line 12 in Shenzhen, China, it is found that the relative difference rate between the predicted value and the measured value is less than 10%, which validates the reliability and accuracy of the prediction model. In addition, by comparing with an existing typical prediction model of the CCS type disc wear, the results show that the calculation results of the prediction model proposed in this paper are more consistent with the field measured values, indicating that the disc cutter wear rate and cutting life can be regarded as reliable indexes to evaluate the cutter wear characteristics, which provides a more reasonable and feasible theoretical basis for the design of tool replacement scheme in TBM engineering.

-

0. 引言

施工或构造挤压易诱发岩石变形甚至破裂,变形速率作为描述岩石变形的重要力学参数,能反映岩石变形与破坏的时效过程,对岩石工程施工安全、灾害预测预警等意义重大,关于岩石应变速率的研究备受重视。张传庆等[1]基于变形速率建立了深埋软岩隧洞围岩稳定性评估方法;Li等[2]指出隧道“三锚”支护时机应根据围岩变形速率作严格要求;曹海静等[3]、张民庆等[4]利用变形速率分析进行隧道三台阶施工围岩变形预留量确定和分级预警。王学滨[5]探究了煤岩弹性段和软化段应变速率对岩石破坏的敏感性;Rosea等[6]用岩体位移分析Fukuzono速度倒数与时间图线,王延平等[7]进一步建立了滑坡预测模型。《公路隧道施工技术规范》[8]和《铁路隧道设计规范》[9]等技术规程中均以变形速率作为隧道围岩稳定性判定的重要依据。此外,Yamamoto[10]提出基于应变速率的DAR地应力测量法,谢强等[11]、王海军等[12]、Hsieh等[13]、葛伟凤等[14]还从声发射、黏聚力、侧向应变、Kaiser效应等不同角度,对DAR测量法进行完善。可见,掌握荷载作用下应变速率的演化规律,对理解岩石变形行为,分析岩石工程稳定性,制定合理的支护方案,以及地应力精准测量等方面具有重要作用。

目前关于岩石应变速率的研究大多针对单调加载作用条件。然而大量工程实践表明,岩石工程在施工和服役过程中,疲劳荷载和应力周期性重分布现象普遍存在,如矿山巷道、高边坡、隧道岩体的分布开挖、库岸边坡岩体受水位周期性大幅升降作用,岩基受通车、地震动态周期荷载等。不少学者已开展了疲劳荷载作用下岩石力学性质的研究工作,如葛修润等[15]、Shahnazari等[16]、Liu等[17-18]通过室内试验和数值模拟方法,分别对岩石在疲劳荷载作用下的变形特性、残余体积应变、动弹性模量等力学行为进行了深入研究。但是,上述研究的重点主要是讨论岩石在疲劳荷载下的强度、残余变形和弹性常数等问题,而对于应变速率,特别是岩石疲劳累积损伤过程的应变速率响应规律研究鲜有报道。

鉴于此,本文进行了不同围压和不同应力比条件下的大理岩等幅循环加卸载三轴压缩试验,研究不同条件下大理岩疲劳累积损伤过程中,弹性模量、损伤因子、轴向应变速率和体变速率等参量的响应规律,并尝试进行循环过程中应变速率和损伤因子的相关性讨论。其规律性认识有助于进一步了解疲劳荷载作用下岩石变形和损伤演化的相关性,为建立基于变形速率的岩石工程安全预警体系和科学支护方法提供参考。

1. 试验条件及方法

1.1 试验条件

试验在华侨大学与长春市科意试验仪器有限公司联合研制的TFD–2000/D型电液伺服三轴压缩试验机上完成,见图1。设备最大围压为200 MPa,最大轴压为2000 kN,应力传感器测量精度0.01 kN。岩样变形采用轴向引伸计(最大量程为10 mm)和环向链式引伸计(最大量程为3 mm),测量分辨率为0.0001 mm。控制系统采用德国DOLI公司的EDC全数字伺服控制器,可实现轴向力控制、轴向变形控制、轴向位移控制、环向变形控制和环向应力控制等多种控制方式。

1.2 试样准备

岩样取自广西贺州市某采石厂白色粗晶粒大理岩,质地均匀,无杂质,少裂隙,完整性和均匀性较好,见图1。按国际岩石力学学会(ISRM)试验规程建议方法,将试样加工50 mm×100 mm(直径×长度)的标准型圆柱试样,并对试样两端面进行磨平,端面平整度在0.02 mm以内,直径误差控制在0.3 mm范围内。试验前,各岩样均经过纵波波速测试,并去除波速异常试样,进一步保证试样一致性。图2为不同围压的单调压缩条件下,大理岩的轴向、环向全应力–应变关系曲线,为后续疲劳试验中确定各围压下疲劳荷载幅值提供依据。为了和疲劳试验中循环加卸载的控制方式一致,单调加载控制方式也设为应力控制。由图2可知,岩样峰值应力随围压的增大而增大,且延性逐渐增强。

1.3 疲劳试验方案

疲劳试验通过等幅循环加卸载方式实现,试验中控制围压和循环幅值两个因素,设置4×4的正交试验,见表1。围压设为0 (单轴条件),2,5,10 MPa,每组围压下的疲劳荷载幅值设置4组应力比,分别为0.90,0.85,0.80,0.75倍峰值应力。由表1可知,各围压的疲劳荷载目标值均大于各自扩容点应力,故4种应力比均超过了岩石的弹性极限。加卸载过程均为应力控制,控制速度为1 MPa/s,直到试样破坏为止,加载方式见示意图3。若500次循环加卸载后试样仍不破坏,则停止循环,改为单调加载方式直至试样破坏。

表 1 不同围压下疲劳荷载的预设目标值Table 1. Fatigue loading under different confining pressures(Mpa) 围压 峰值应力 应力比 扩容点应力 0.90 0.85 0.80 0.75 0 50.00 45.00 42.50 40.00 37.50 34.0 2 60.00 54.00 51.00 48.00 45.00 43.4 5 72.00 64.80 61.25 57.60 54.00 52.3 10 93.00 83.70 79.05 74.60 69.75 65.0 2. 应力–应变关系及弹性参数分析

2.1 应力–应变关系

表2为不同应力比和不同围压下,大理岩受疲劳荷载作用破坏时所需的循环次数。由表2可知:相同应力比疲劳荷载条件下,随着围压的增大,岩样越来越难以破坏。说明围压对环向变形的约束对疲劳劣化有明显的抑制作用,使大理岩抗疲劳承载能力增强。图4为单轴疲劳荷载下大理岩应力–应变关系曲线(有围压下的岩石变形差异性与图4类似,篇幅所限不再列出),其中体积应变(以下简称为体变)由

εv =ε1 +2ε2 计算得到(εv 为体变,ε1 为轴向应变,ε2 为环向应变)。由图4可见:①在单轴压缩条件下,随着应力比的增大,大理岩破坏时所需的循环荷载次数降低;②随着循环次数增加残余应变不断发展,滞回圈也随之沿应变坐标轴向右移动,且应力比越高移动越显著;③第一次加卸载产生明显的残余应变,滞回圈面积较大。自第二次加载开始,随着循环次数增加滞回圈相互重叠、缓慢右移,临近破坏时滞回圈加速右移且面积明显增大。上述现象可解释为相同围压下,应力比越大疲劳应力超越弹性极限程度也就越大,使单次循环加卸载过程中的塑性变形更大,导致相同循环次数后岩样累计残余变形也就越大。发生破坏岩样的前期循环以弹性变形为主,塑性变形较小,故滞回圈缓慢右移,而当残余变形累积到一定程度后,循环加卸载过程中塑性变形增加,故滞回圈增大且加速右移。表 2 岩样破坏情况及循环次数Table 2. Failure situation of rock samples and number of cycles at failure应力比 围压 0 MPa 2 MPa 5 MPa 10 MPa 0.90 10 16 33 未破坏 0.85 19 22 未破坏 未破坏 0.80 50 未破坏 未破坏 未破坏 0.75 未破坏 未破坏 未破坏 未破坏 需强调的是,第一次加载时,由于受到超过历史最大应力水平的作用(即岩石具有的“记忆性”),岩样产生较大的残余变形和滞回圈面积[19]。从第二次循环加载开始,岩石受到的疲劳荷载应力水平与第一次加卸载相等,其力学行为与第一次的超过应力历史加卸载有较大区别。第二次加载开始才是真正意义上的等幅疲劳累积损伤过程,因此在分析弹性模量、损伤因子和应变速率的演化规律时,将第二次加载作为疲劳损伤的初始状态进行分析。

2.2 弹性模量变化规律

图5为不同围压下弹性模量E(E=

Δσ/Δε ,Δσ ,Δε 取该围压下单调压缩峰值50%偏应力附近5 MPa左右的应力差值和对应的应变差值)与循环次数的关系曲线。由图5可见:①自第二次循环荷载开始,随着循环次数的增加,发生疲劳破坏岩样的弹性模量逐渐下降,且围压越大下降越平缓。未发生疲劳破坏的岩样在0.90,0.85应力比下,弹性模量先小幅下降后缓慢上升,最后逐渐趋于稳定;在0.80,0.75应力比下,弹性模量小幅升高后趋于稳定。②在循环次数相同,应力比也相同时,随着围压的提高弹性模量有不同程度的提高;在相同围压和循环次数下,随着应力比的降低,弹性模量也有不同程度的提高。以上现象解释如下:①随循环次数增加,发生疲劳破坏岩样因受多次的较高应力作用,内部裂隙不断扩展、交汇、贯通,抗变形能力不断下降,导致弹性模量下降越来越快。由于围压对岩样的裂隙开展有抑制作用,围压越大弹性模量下降越缓慢。未发生疲劳破坏的岩样在0.80,0.75应力比下,距离弹性极限对应的应力比较近,几乎不会产生塑性变形和累积损伤效应。根据文献[20,21]对疲劳变形和蠕变(也被称为“应力疲劳”)中应变硬化现象的解释:较低应力的疲劳荷载导致裂隙面相互作用和晶象学优势面出现,晶粒边界处产生的位错堆积阻碍位错运动的后续发展,岩石内微裂隙压密闭合更为充分,颗粒排列更加密实,裂隙总数相对减少,产生裂隙面“黏溶”的自愈合现象,因此弹性模量随循环次数增加会缓慢上升。当硬化至一定程度,岩石进入近似弹性状态的变形阶段,弹性模量趋于稳定。文献[20]还指出,疲劳应变硬化阶段也可能存在着稍许软化现象。在0.90,0.85应力比条件下的前几次循环加卸载过程中,较高应力的疲劳荷载产生的岩石内部损伤使弹模下降,即软化现象占主导。之后硬化作用越来越明显,故弹性模量随循环次数增加开始缓慢上升并最终稳定。②围压升高可使岩石晶粒间更加紧凑,裂隙发展段的应力门槛值提高,抗变形能力增大,从而出现围压越高岩样弹性模量越高的现象。

3. 应变速率演化特征

3.1 疲劳作用对应变速率的影响

为分析疲劳荷载作用过程中应变速率的演化特征,图6(a),(b)分别为应力比为0.90的单轴(低周)疲劳作用下,第2,4,6,8,10次加载和第2,4,6,8次卸载过程中岩石偏应力、轴向应变速率与轴向应变的关系曲线,其中轴向应变速率通过对时间求差分的方式获得,由

ε′=(εt1−εt2)/(t1−t2) 计算得到。εt1,εt2分别表示相邻时刻的应变。由于不同围压和应力比条件下破坏岩样的曲线形态大致相同,未破坏岩样曲线形态接近弹性状态,考虑篇幅不再列出。由图6可见:①随循环次数增加,残余应变(即当次卸载终了和下一次加载初始时刻应变值)不断增大。②每次加载时岩样的轴向变形曲线形态类似,均经历曲线下凹的裂隙压密阶段、斜直线的弹性变形阶段以及曲线上凸的塑性变形阶段。轴向应变速率随应变发展均呈现先减小后趋稳,最后逐渐增大的“U”型演化规律,且不同循环次数下稳定段对应的应变速率值基本保持一致。③末次加载前,岩样轴向应变速率始终保持在相对较低的水平上,加载初始和终了时刻的轴向应变速率与其对应的残余应变均呈线性正相关关系。末次加载至接近目标荷载时,轴向应变速率明显突增,岩样随即破坏。④每次加载进入速率稳定段时刻的偏应力与其对应的轴向应变呈线性正相关关系,加载超出速率稳定段时刻偏应力与其对应的轴向应变呈线性负相关关系,应变速率曲线稳定段长度随加卸载次数增加明显缩短。⑤每次卸载时岩样大致经历了近似线性的回弹和非线性回弹两个阶段。轴向应变速率呈现先小幅度上升后趋稳,最后增大的倒“S”型演化规律,且卸载初始与终了时刻的轴向应变速率绝对值与其对应的残余应变也呈线性正相关关系。卸载进入速率稳定段时刻的偏应力较接近,跃出速率稳定段时刻的偏应力与其对应的轴向应变呈线性正相关关系。

以上现象解释如下:①因塑性变形不可逆,随加载次数增加积累越来越大,故残余应变也越来越大。②加载开始时岩样内部原有裂隙随应力增加逐渐闭合,岩样抵抗变形的能力逐渐提高,轴向应变速率逐渐减小,待岩样达到最致密状态时进入弹性变形阶段,应变速率保持稳定。偏应力进一步增加后,原生裂隙张开,新生裂隙开始增多,岩样发生塑性变形,故应变速率显著增大。稳定段应变速率基本一致说明不同循环加载次数下,岩样的最致密状态较接近,抵抗变形的能力亦较接近,临近破坏时应变速率迅速增大则反映了岩石接近失稳的变形状态(图7为不同围压、不同应力比下稳定段应变速率图,显示了围压越大速率越低的规律,可与图5中围压越大弹性模量越高的现象相互印证)。③试验结果显示加载初始和终了时刻的轴向应变速率与残余应变均呈线性正相关关系,张世殊等[22]采用残余变形表征岩石损伤,从这个角度不难推断,加载初始和终了时刻的轴向应变速率也可反映疲劳作用下岩样的累积损伤进程(应变速率与弹模表征的损伤因子间的相关性在下一节讨论)。④随加卸载次数增加,岩样内部裂隙的长度、宽度、密度均不断增大,维持岩样稳定的内部结构单元体不断被破坏,损伤不断累积。加载至弹性段后随着轴向应力增加,稳定的单元体不断减少,岩样结构稳定性下降,裂隙越来越难以维持闭合状态,应变速率在经历短暂稳定阶段后很快又因裂隙的重新扩展贯通而快速上升,故应变速率稳定段随加载次数增加而缩短。⑤与加载一样,每次卸载初始和终了时刻的轴向应变速率也可反映疲劳作用下的累积损伤进程。

图8(a),(b)分别为应力比=0.90的单轴疲劳作用下,第2,4,6,8,10次加载和第2,4,6,8次卸载过程中岩石偏应力、体变速率与体变(以下简称体变)的关系曲线。由图8可见:①随循环次数增加,残余体变(即当次卸载终了和下一次加载初始时刻的体变值)的绝对值不断增大。②每次加载时岩样的体变曲线形态类似,均经历先体缩(体变增量为正值)至扩容点,之后体胀(体变增量为负值)的体变过程。体缩阶段的体变速率先快速减小,再进入平缓段,之后加速下降,至扩容点时体变速率降至0,进入体胀阶段后体变速率绝对值快速增大,整体上体变速率随体变发展呈反“L”型演化趋势。③末次加载前,岩样体变速率均保持在相对较低的水平,加载初始和终了阶段的体变速率绝对值都与其对应的残余体变绝对值呈线性正相关关系。末次加载至接近目标荷载时,体变应变速率绝对值明显突增。④随循环次数增加,每次加载到扩容点时对应的偏应力逐渐减小,且偏应力与其对应的体变绝对值呈线性负相关关系。⑤卸载阶段岩样体积始终处于膨胀过程,体变速率绝对值整体呈先减小再稳定最后加速增长的“U”型演化趋势,且稳定段对应的体变速率值基本保持不变。卸载初始与终了时刻的体变速率绝对值与其对应的残余体变绝对值呈线性正相关关系,且终了时刻体变速率绝对值较大。此外,卸载进入体变速率稳定段时刻对应的偏应力较接近,跃出体变速率稳定段时刻的偏应力与其对应的体变绝对值呈线性正相关关系。

以上现象解释如下:①与残余应变一样,因塑性变形积累,残余体变随循环次数增加而增大。②岩石变形全过程可依次分为裂隙压密、弹性变形、裂隙稳定扩展和非稳定扩展4阶段,体缩段包含前3个阶段。在体缩段初期的裂隙压密阶段,岩石内部越来越密实,抵抗变形能力增强,体变速率快速减小,进入弹性变形阶段体变速率变化趋于平缓,进入裂隙稳定扩展阶段后体变速率又快速下降,达到扩容点时体变增量为0,故体变速率为0。超越扩容点后岩石进入裂隙非稳定扩展段,裂隙快速交汇贯通,体变速率加速增加。③与应变速率类似,加载初始和终了时刻的体变速率绝对值与残余体变绝对值呈线性正相关关系,表明此刻的体变速率也可反映疲劳作用过程中岩样的累积损伤进程。④随循环次数增加,损伤也随之积累增加,闭合裂隙也易被更低的偏应力再次激活,岩样承载能力不断下降,使扩容点越来越早出现。⑤与加载一样,每次卸载初始和终了时刻的体变速率也可反映疲劳作用过程中岩样的累积损伤进程。

3.2 初始应变速率与损伤因子关系

损伤因子可直接表征岩石的损伤程度,为研究不同围压、不同应力比疲劳作用下岩石的损伤累积进程、应变速率演化及其相互关系,作出不同围压和不同应力比下,自第二次加卸载开始的岩样损伤因子与循环次数的关系图,见图9。其中损伤因子由常规的弹性模量法算出(

D=1−E/E0 ,E0 为第二次加载时的弹性模量)。如图9所示:①发生疲劳破坏岩样的损伤因子随循环次数增加不断增大,循环至后期损伤因子爆发式增大,直观体现了疲劳荷载下岩石的累计损伤进程;②未发生疲劳破坏岩样的损伤因子先小幅波动后逐渐趋于稳定;③无论破坏或未破坏,应力比越低或围压越大,相同循环次数时岩样的损伤因子越小,较大围压和较低应力比下损伤因子最终稳定至负值,这可能是因为较大的围压使疲劳荷载对岩石产生了小幅硬化作用[20]。同样的,自第二次加卸载开始绘制加载时刻初始轴向应变速率(以下简称为初始速率)与循环次数的关系曲线,见图10。由图10可知:①发生疲劳破坏岩样的初始速率随循环次数增加不断增大,循环至后期初始速率爆发式增大;②未发生疲劳破坏岩样的初始速率先小幅波动后逐渐趋于稳定;③无论破坏或未破坏,应力比越低或围压越大,相同循环次数时岩样的初始速率越小。需强调的是,图10与图9对比可见,两类关系曲线的演化规律几乎是一致的,进一步验证了图6的分析结论,即加载初始应变速率可反映岩石的损伤程度,也就是当次循环的初始轴向应变速率可表征其之前循环过程中的损伤累积情况。

为进一步分析初始速率与损伤因子的定量关系,参照损伤因子计算形式对初始速率进行归一化处理,

D′=1−V1/V (V1 取第二次加载时的初始速率,V 为之后循环加载的初始速率,D′ 为归一化初始速率),对疲劳破坏岩样绘制D′ 与损伤因子的线性拟合关系图,见图11,拟合相关度见表3。由图11和表3可见,不同围压和应力比下,破坏岩样的线性拟合相关度均在0.991以上,说明可以利用初始速率表征损伤因子,D=K(1−V1/V) (K为受围压与循环应力比影响的拟合系数,K值随围压的增大而减小,随应力比降低而减小)。表 3 疲劳破坏岩样归一化初始速率与损伤因子相关性Table 3. Correlation fitting between normalized initial rate and damage factor of damaged rock samples应力状态 围压/MPa K值 相关度 拟合函数 0.90倍峰值 0 0.74676 0.99959 D=KD′ 2 0.59077 0.99732 5 0.49197 0.99700 0.85倍峰值 0 0.38372 0.99154 2 0.32274 0.99732 0.80倍峰值 0 0.27233 0.99492 图12为10 MPa围压的不同应力比下岩石归一化速率与损伤因子关系图。由图12可见:①未破坏岩样在前期循环加卸载阶段归一化速率与损伤因子基本符合线性关系,而在后期循环加卸载时出现回缩和聚拢现象。这是由于未破坏岩样在疲劳累积损伤作用至一定程度后不再继续劣化,而开始出现不同幅度的硬化现象,损伤因子和归一化速率不增反降,致使整个曲线呈“弯钩”型。②应力比为0.90,0.85时,曲线位于损伤因子与归一化速率为正值的第一象限。而当应力比为0.80,0.75时,由于应力比较低,累积损伤非常微弱,此时硬化作用起主导,循环加卸载的硬化作用使损伤因子出现负值情况,变形速率也随之降低,故关系曲线位于速率为正,损伤因子为负的第四象限。总体上呈现随应力比降低,曲线沿顺时针方向分布,且应力比越低弯曲回缩现象越明显的变化趋势。

4. 结论

(1)相同围压下,随应力比升高,岩样疲劳破坏需经历的循环加卸载次数减少;相同应力比下,随围压增大,岩样越来越难以破坏。发生疲劳破坏岩样的弹性模量随循环次数增加迅速减小。

(2)发生疲劳破坏的岩样在每次加载时轴向应变速率随轴向应变发展呈“U”型演化规律,体变速率随体变发展呈反“L”型演化趋势,且加载初始和终了时刻的轴向应变速率与其对应的残余应变均呈线性正相关关系,体变速率绝对值与其对应的残余体变绝对值呈线性正相关关系。

(3)发生疲劳破坏的岩样在每次卸载时轴向应变速率随轴向应变发展呈倒“S”型演化规律,体变速率随体变发展呈“U”型演化趋势,且卸载初始与终了时刻的轴向应变速率与其对应的残余应变呈线性正相关关系,体变速率与其对应的残余体变绝对值呈线性正相关关系。

(4)当次循环加载的初始轴向应变速率可表征其之前循环过程中的损伤累积程度。发生疲劳破坏岩样的归一化初始速率后与损伤因子有良好的线性关系,系数K随围压增大或应力比值减小而减小。未发生疲劳破坏岩样的归一化速率和损伤因子关系曲线产生“弯钩”型回缩现象。

-

表 1 国内外现有典型的盘形滚刀磨损预测模型

Table 1 Existing domestic and foreign typical disc cutter wear prediction models

预测模型 原理或方法 公式 数据范围 应用情况 CSM[6] 岩石挤压与剪切破坏理论、LCM试验 FV=8.76T0.797R0.788φ0.602S0.28σ0.629cσ0.195t — 完整性较好的玄武岩、石灰岩、花岗岩 NTNU[7] 挪威磨蚀性试验(SJ、AVS) Hf=π D2⋅H0⋅ki⋅PR4N 超过250 km隧道 花岗岩、凝灰岩 魏南珍等[8] 现场磨损数据拟合 M=0.0229R2i+2431Ri−3.2245 约3.7 km秦岭隧道 混合花岗岩和混合片麻岩 张照煌等[9] 岩石挤压、剪切及张拉破坏理论 FV=KAP2f⋅P 约5.6 km秦岭隧道 完整性较好的混合花岗岩 Frenzel等[10] Cerchar磨蚀性试验(CAI) Hf=π D24⋅n⋅P1000⋅2SD⋅1000 超过127 km隧道 微风化花岗岩 Hassanpour等[11] 岩石硬度试验(VHNR) Hf=−2.669VHNR−7.891UCS+3430.955 约30 km长Karaj输水隧洞 弱风化火山岩 李刚等[12] CSM模型 Ft=TRϕPr1 + ψ, Pr=C⋅(Sσ2cσtφ√RT)1/3 约18.5 km秦岭隧道 完整较好的玄武岩、石灰岩、花岗岩 杨延栋等[13] Rabinowicz微切削原理 ω=0.16KsS13RiσcD0T16h16σs 约2 km狮子洋隧道和531 m广州地铁隧道 微风化混合花岗岩 注:Fv为滚刀法向垂直力(N),Hf为滚刀基本寿命(m3/cutter),M为滚刀径向磨损量(mm),Ft为滚刀法向和切向合力(N)。 表 2 复合式土压平衡盾构机技术参数

Table 2 Technical parameters of composite EPB shield machine

参数 整机功率/kW 刀盘转速/(r·min-1) 扭矩/(kN·m) 推力/kN 推进速度/(mm·min-1) 刀盘开口率/% 滚刀数量/把 计算值 1668.05 1.8 2300 10000 15 35 41 参数 中心滚刀数量/把 正面滚刀数量/把 边滚刀数量/把 滚刀直径/mm 刀刃宽度/mm 刀刃角/(°) 刀圈硬度/HRC 计算值 6 23 12 457 19 20 60 表 3 微风化花岗岩力学性质及计算参数

Table 3 Mechanical properties and calculation parameters of slightly weathered granulated granite

参数 密度/(kg·m-3) 抗压强度/MPa 抗拉强度/MPa 黏聚力/MPa 内摩擦角/(°) 弹性模量/GPa 泊松比 完整性系Kv 滚压系Kn 计算值 2700 90 6.89 20.8 42.5 26.7 0.22 0.55 0.7 -

[1] KARAMI M, ZARE S, ROSTAMI J. Study of common wear prediction models for hard rock TBM disc cutters and comparison with field observation in Kerman water conveyance tunnel[J]. Bulletin of Engineering Geology and the Environment, 2021, 80(2): 1467–1476. doi: 10.1007/s10064-020-01987-5

[2] TUMAC D, BALCI C. Investigations into the cutting characteristics of CCS type disc cutters and the comparison between experimental, theoretical and empirical force estimations[J]. Tunnelling and Underground Space Technology, 2015, 45: 84–98. doi: 10.1016/j.tust.2014.09.009

[3] 张照煌. 全断面岩石掘进机平面刀盘上盘形滚刀磨损研究[J]. 现代隧道技术, 2007, 44(6): 32–36. doi: 10.3969/j.issn.1009-6582.2007.06.007 ZHANG Zhao-huang. Study on the abrasion of disc cutters on full face rock tunnel boring machine[J]. Modern Tunnelling Technology, 2007, 44(6): 32–36. (in Chinese) doi: 10.3969/j.issn.1009-6582.2007.06.007

[4] YANG J H, ZHANG X P, JI P Q, et al. Analysis of disc cutter damage and consumption of TBM1 section on water conveyance tunnel at Lanzhou water source construction engineering[J]. Tunnelling and Underground Space Technology, 2019, 85: 67–75. doi: 10.1016/j.tust.2018.11.040

[5] XUE Y D, ZHAO F, ZHAO H X, et al. A new method for selecting hard rock TBM tunnelling parameters using optimum energy: a case study[J]. Tunnelling and Underground Space Technology, 2018, 78: 64–75. doi: 10.1016/j.tust.2018.03.030

[6] ROSTAMI J. Development of A Force Estimation Model for Rock Fragmentation with Disc Cutters Through Theoretical Modeling and Physical Measurement of Crushed Zone Pressure[D]. Golden: Colorado School of Mines, 1997.

[7] BRULAND A. Hard Rock Tunnel Boring[D]. Trondheim: Norwegian University of Science and Technology, 1998.

[8] 魏南珍, 沙明元. 秦岭隧道全断面掘进机刀具磨损规律分析[J]. 石家庄铁道学院学报, 1999, 12(2): 86–89. https://www.cnki.com.cn/Article/CJFDTOTAL-SJZT902.022.htm WEI Nan-zhen, SHA Ming-yuan. The analysis of TBM cutter wear characteristic in the construction of Qinling tunnel[J]. Journal of Shijiazhuang Railway Institute, 1999, 12(2): 86–89. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-SJZT902.022.htm

[9] 张照煌, 纪昌明. 全断面岩石掘进机盘形滚刀刃破岩点弧长的解析解及应用研究[J]. 应用基础与工程科学学报, 2009, 17(2): 265–273. doi: 10.3969/j.issn.1005-0930.2009.02.012 ZHANG Zhao-huang, JI Chang-ming. Analytic solution and it's usage of arc length of rock breakage point of disc edge on full face rock tunnel boring machine[J]. Journal of Basic Science and Engineering, 2009, 17(2): 265–273. (in Chinese) doi: 10.3969/j.issn.1005-0930.2009.02.012

[10] FRENZEL C. Disc cutter wear phenomenology and their implications on disc cutter consumption for TBM[C]// 45th US Rock Mechanics/Geomechanics Symposium, 2011, San Francisco.

[11] HASSANPOUR J, ROSTAMI J, AZALI S T, et al. Introduction of an empirical TBM cutter wear prediction model for pyroclastic and mafic igneous rocks; a case history of Karaj water conveyance tunnel, Iran[J]. Tunnelling and Underground Space Technology, 2014, 43: 222–231. doi: 10.1016/j.tust.2014.05.007

[12] 李刚, 朱立达, 杨建宇, 等. 基于CSM模型的硬岩TBM滚刀磨损预测方法[J]. 中国机械工程, 2014, 25(1): 32–35. doi: 10.3969/j.issn.1004-132X.2014.01.007 LI Gang, ZHU Li-da, YANG Jian-yu, et al. A method to predict disc cutter wear extent for hard rock TBMs based on CSM model[J]. China Mechanical Engineering, 2014, 25(1): 32–35. (in Chinese) doi: 10.3969/j.issn.1004-132X.2014.01.007

[13] 杨延栋, 陈馈, 李凤远, 等. 盘形滚刀磨损预测模型[J]. 煤炭学报, 2015, 40(6): 1290–1296. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201506010.htm YANG Yan-dong, CHEN Kui, LI Feng-yuan, et al. Wear prediction model of disc cutter[J]. Journal of China Coal Society, 2015, 40(6): 1290–1296. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201506010.htm

[14] 吴俊, 袁大军, 李兴高, 等. 盾构刀具磨损机理及预测分析[J]. 中国公路学报, 2017, 30(8): 109–116, 142. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGGL201708012.htm WU Jun, YUAN Da-jun, LI Xing-gao, et al. Analysis on wear mechanism and prediction of shield cutter[J]. China Journal of Highway and Transport, 2017, 30(8): 109–116, 142. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGGL201708012.htm

[15] SU W L, LI X G, JIN D L, et al. Analysis and prediction of TBM disc cutter wear when tunneling in hard rock strata: a case study of a metro tunnel excavation in Shenzhen, China[J]. Wear, 2020, 446/447: 203190. doi: 10.1016/j.wear.2020.203190

[16] 龚秋明, 何冠文, 赵晓豹, 等. 掘进机刀盘滚刀间距对北山花岗岩破岩效率的影响实验研究[J]. 岩土工程学报, 2015, 37(1): 54–60. http://manu31.magtech.com.cn/Jwk_ytgcxb/CN/abstract/abstract16037.shtml GONG Qiu-ming, HE Guan-wen, ZHAO Xiao-bao, et al. Influence of different cutter spacings on rock fragmentation efficiency of Beishan granite by TBM[J]. Chinese Journal of Geotechnical Engineering, 2015, 37(1): 54–60. (in Chinese) http://manu31.magtech.com.cn/Jwk_ytgcxb/CN/abstract/abstract16037.shtml

[17] 余静. 岩石机械破碎规律和破岩机理模型[J]. 煤炭学报, 1982, 7(3): 10–18. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB198203001.htm YU Jing. Rules of rock fragmentation with mechanical methods and model of rock failure mechanism[J]. Journl of China Coal Society, 1982, 7(3): 10–18. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB198203001.htm

[18] 孙伟, 张旭, 赵奎山. 基于密实核理论的单滚刀多阶段受力预测模型[J]. 机械设计与制造, 2015(6): 9–12. https://www.cnki.com.cn/Article/CJFDTOTAL-JSYZ201506004.htm SUN Wei, ZHANG Xu, ZHAO Kui-shan. Multi-stage force prediction model of single disc cutter based on the dense nuclear theory[J]. Machinery Design & Manufacture, 2015(6): 9–12. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JSYZ201506004.htm

[19] HUO J Z, WANG W Z, SUN W, et al. The multi-stage rock fragmentation load prediction model of tunnel boring machine cutter group based on dense core theory[J]. The International Journal of Advanced Manufacturing Technology, 2017, 90(1/2/3/4): 277–289.

[20] 张桂菊, 谭青, 劳同炳. TBM盘形滚刀切削力学模型分析[J]. 中南大学学报(自然科学版), 2020, 51(10): 2792–2799. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD202010011.htm ZHANG Gui-ju, TAN Qing, LAO Tong-bing. Analysis of rock breaking mechanics model for TBM disc cutter[J]. Journal of Central South University (Science and Technology), 2020, 51(10): 2792–2799. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD202010011.htm

[21] 赵海鸣, 舒标, 夏毅敏, 等. 基于磨料磨损的TBM滚刀磨损预测研究[J]. 铁道科学与工程学报, 2014, 11(4): 152–158. https://www.cnki.com.cn/Article/CJFDTOTAL-CSTD201404027.htm ZHAO Hai-ming, SHU Biao, XIA Yi-min, et al. Study of wear prediction for TBM cutter based on abrasive wear model[J]. Journal of Railway Science and Engineering, 2014, 11(4): 152–158. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-CSTD201404027.htm

[22] RABINOWICZ, E. Friction and Wear of Materials[M]. NewYork: John Wiley & Sons, 1995.

[23] RABINOWICZ E, DUNN L A, RUSSELL P G. A study of abrasive wear under three-body conditions[J]. Wear, 1961, 4(5): 345–355.

[24] 龚秋明. 掘进机隧道掘进概论[M]. 北京: 科学出版社, 2014. GONG Qiu-ming. Introduction to Tunneling with TBMs[M]. Beijing: Science Press, 2014. (in chinese)

[25] 荆留杰, 张娜, 杨晨, 等. 基于最小破碎比能TBM滚刀间距设计方法研究[J]. 铁道学报, 2018, 40(12): 123-129. https://www.cnki.com.cn/Article/CJFDTOTAL-TDXB201812019.htm JING Liu-jie, ZHANG Na, YANG Chen, et al. A design method research on TBM face cutter spacing layout based on mnimum specific energy[J]. Journal of the China Railway Society, 2018, 40(12): 123–129. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-TDXB201812019.htm

[26] 徐小荷, 余静. 岩石破碎学[M]. 北京: 煤炭工业出版社, 1984. XU Xiao-he, YU Jing. Rock Breakage Thoery[M]. Beijing: China Coal Industry Publishing House, 1984. (in Chinese)

[27] ROSTAMI J. Study of pressure distribution within the crushed zone in the contact area between rock and disc cutters[J]. International Journal of Rock Mechanics and Mining Sciences, 2013, 57: 172–186.

-

期刊类型引用(18)

1. 宋健,潘驭航,陆朱汐,姬建,张飞,高玉峰. 考虑场地效应的多点地震动作用下边坡永久位移分析. 岩土工程学报. 2025(01): 65-75 .  本站查看

本站查看

2. 刘中宪,卢飞龙,边煜凯,黄振恩. 甘肃文县城关镇山体-沉积河谷三维地震动IBEM模拟. 防灾减灾工程学报. 2025(01): 1-12 .  百度学术

百度学术

3. 刘中宪,周涛,黄振恩,黄磊,章博峰. 基于快速边界元方法的倾滑断层近场效应和盆地聚焦效应耦合作用研究. 应用力学学报. 2024(04): 896-906 .  百度学术

百度学术

4. 陈家旺,黄博,凌道盛,王楠. SV波斜入射作用下梯形沉积河谷场地地震动分析. 地基处理. 2024(05): 434-443 .  百度学术

百度学术

5. 范观盛,黄靥欢,刘春,乐天呈. 基于MatDEM的岩石应力波传播与衰减特性敏感性分析. 高校地质学报. 2023(03): 479-486 .  百度学术

百度学术

6. 何卫平,李小军,杜修力,姚惠芹. P波入射分界面叠加区质点运动形成机制与峰值规律. 振动与冲击. 2023(18): 81-87+163 .  百度学术

百度学术

7. 蔡曼琳,丁海平,于彦彦. 圆弧形沉积谷地在平面SV波入射下地震响应的有限元分析. 世界地震工程. 2022(01): 229-240 .  百度学术

百度学术

8. Zhihui Zhu,Yongjiu Tang,Zhenning Ba,Kun Wang,Wei Gong. Seismic analysis of high-speed railway irregular bridge–track system considering V-shaped canyon effect. Railway Engineering Science. 2022(01): 57-70 .  必应学术

必应学术

9. 蔡曼琳. 圆弧形沉积谷地在平面SV波入射下地震响应. 四川建材. 2022(05): 63-64 .  百度学术

百度学术

10. 阙仁波. 对地震危险性分析的示例性探讨. 四川建筑科学研究. 2022(03): 10-19 .  百度学术

百度学术

11. 常晁瑜,薄景山,乔峰,段玉石,张毅毅. 地震动强度对黄土地震滑坡后壁形态的影响. 自然灾害学报. 2022(03): 106-115 .  百度学术

百度学术

12. Mohsen Isari,Reza Tarinejad. Introducing an effective coherence function to generate non-uniform ground motion on topographic site using time-domain boundary element method. Earthquake Engineering and Engineering Vibration. 2021(01): 89-100 .  必应学术

必应学术

13. 李郑梁,李建春,刘波,聂萌萌. 浅切割的高山峡谷复杂地形的地震动放大效应研究. 工程地质学报. 2021(01): 137-150 .  百度学术

百度学术

14. 权雪瑞,黄靥欢,刘春,郭长宝. 川藏铁路线V形深切河谷地形地震放大效应数值模拟. 现代地质. 2021(01): 38-46 .  百度学术

百度学术

15. 刘中宪,刘英,孟思博,黄磊. 基于间接边界元法的近断层沉积谷地地震动模拟. 岩土力学. 2021(04): 1141-1155+1169 .  百度学术

百度学术

16. 梁建文,吴孟桃,巴振宁. 流体饱和半空间二维地形三分量弹性波散射间接边界元模拟. 地球物理学报. 2021(08): 2766-2779 .  百度学术

百度学术

17. 邓鹏. 单体边坡地形的地震动力响应及其放大效应的数值分析. 地震学报. 2020(03): 349-361+378 .  百度学术

百度学术

18. 孔宪京,周晨光,邹德高,余翔. 高土石坝-地基动力相互作用的影响研究. 水利学报. 2019(12): 1417-1432 .  百度学术

百度学术

其他类型引用(23)

下载:

下载: