Experimental study on surface erosion resistances and mechanical behavior of MICP-FR-treated calcareous sand

-

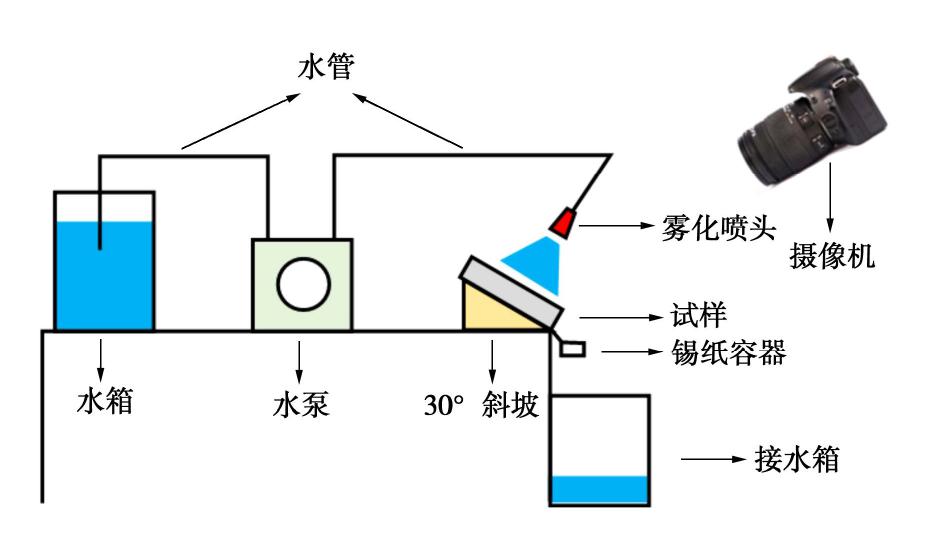

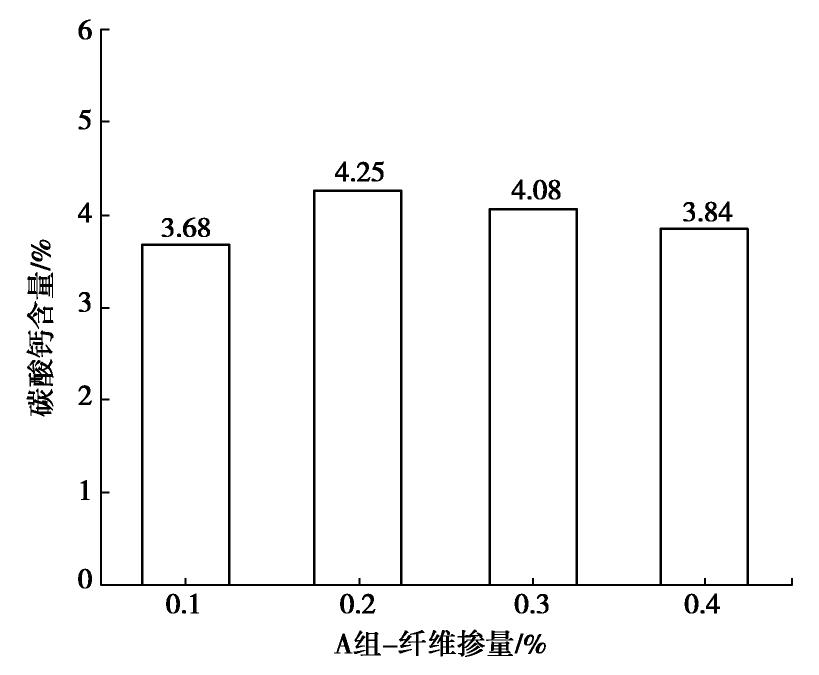

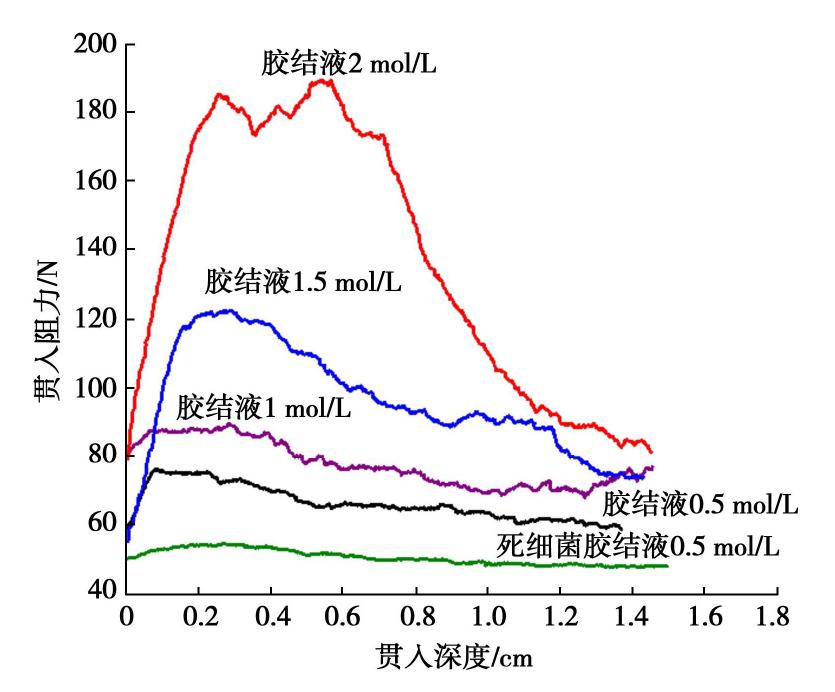

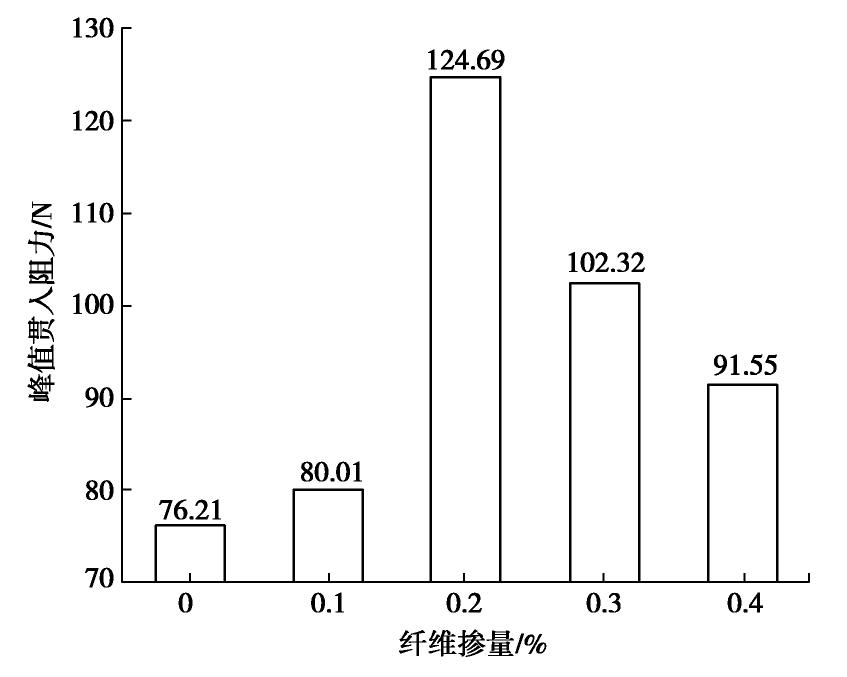

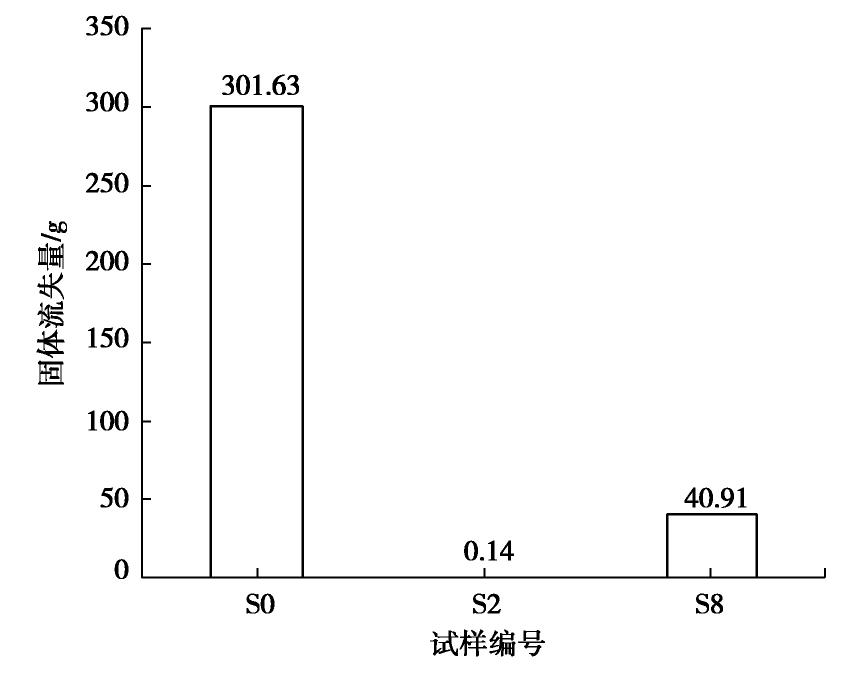

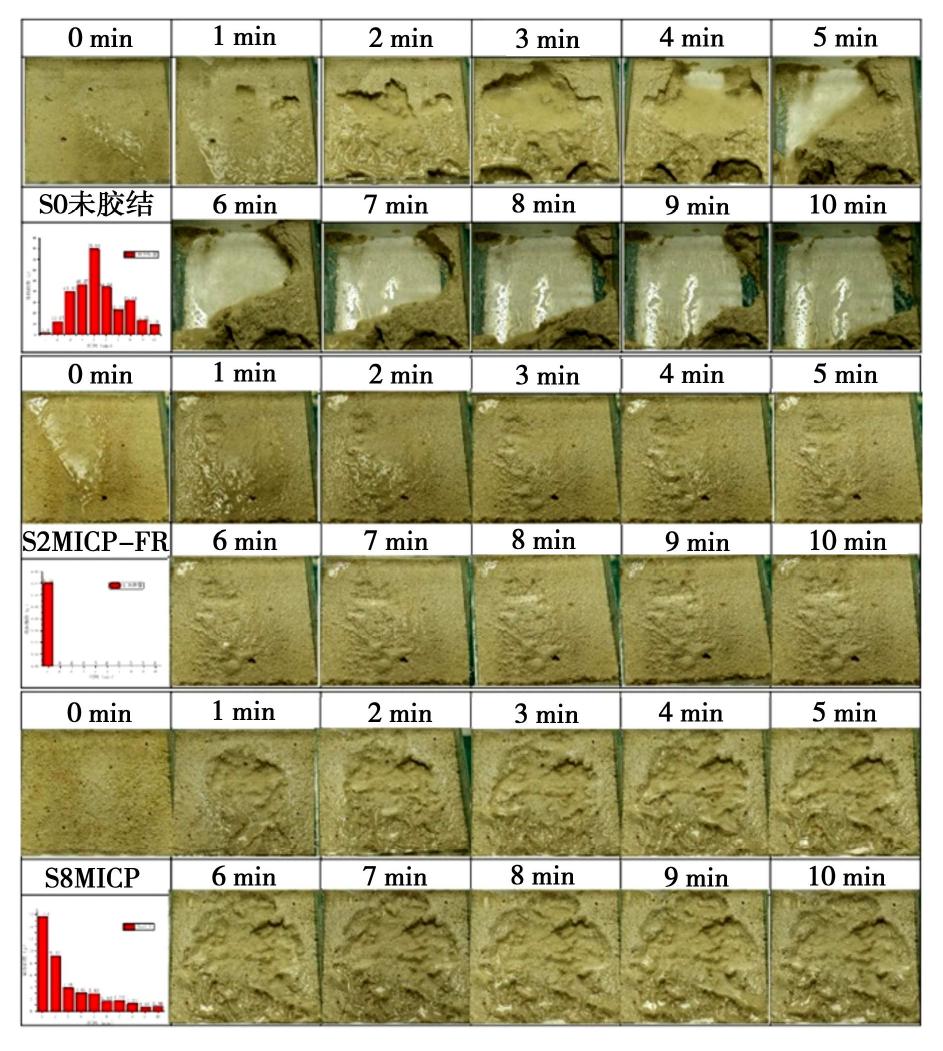

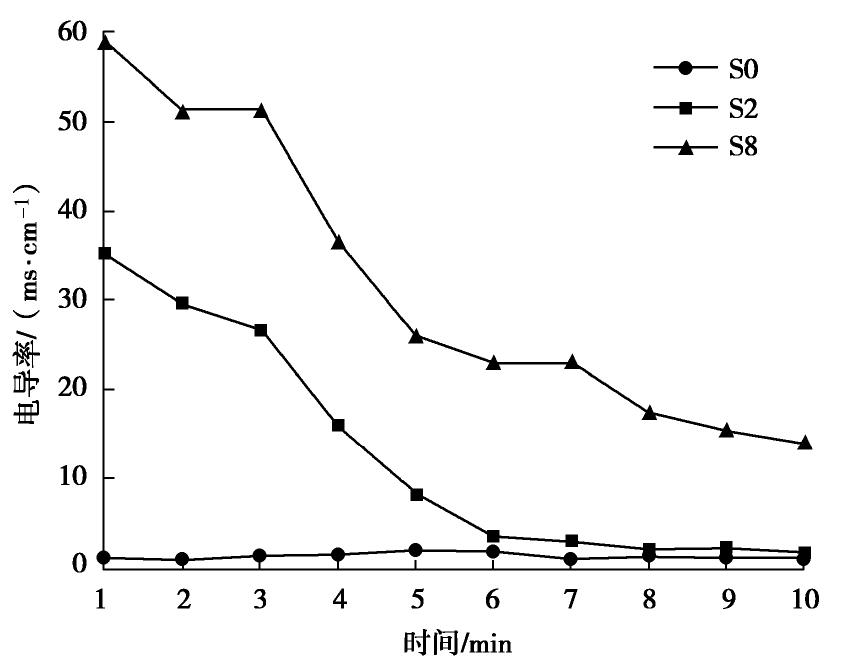

摘要: 南海岛礁是中国“一带一路”建设的重要支撑。作为岛礁工程的主要建筑材料和地基,钙质砂具有高孔隙、易破碎和强度低等不良特性,难以直接满足工程建设要求。为了改善钙质砂的力学特性,并减少极端暴雨冲刷导致的侵蚀问题,提出微生物诱导碳酸钙沉积(MICP)协同纤维加筋(FR)改性技术,采用喷淋工艺,对浅表层钙质砂进行改性处理,并考虑胶结液浓度(0.5,1.0,1.5,2.0 mol/L)和纤维掺量(0.1%,0.2%,0.3%,0.4%)对处理效果的影响。通过开展超微型贯入及模拟暴雨冲刷试验,结合冲刷后滤出溶液的电导率变化,对比分析了不同处理方式下钙质砂的胶结固化程度和抗侵蚀能力。研究结果表明:①MICP技术可以有效胶结钙质砂,改善其力学性质,胶结液浓度越高,试样碳酸钙含量和贯入阻力越高,2.0 mol/L固化效果最佳;②纤维的加入能显著提升MICP的固化效果,纤维掺量对微生物固化试样的力学特性有重要影响,峰值贯入阻力随纤维掺量先增加后减小,最优纤维掺量为0.2%;③经过MICP固化处理后,试样在模拟暴雨条件下表现出较好的抗雨蚀能力,侵蚀量小于未处理试样的1/7,加入纤维后胶结试样的抗侵蚀能力更佳。MICP-FR协同作用可以高效改善钙质砂的工程特性,能在岛礁建设、海岸开发过程中发挥积极作用。Abstract: The islands and reefs in South China Sea are an important support for China's "One Belt and One Road Initiative". As the main building material and foundation of construction on the islands and reefs, the calcareous sand has the bad characteristics of high porosity, easy breakage and low strength, so it is difficult to directly meet the requirements of engineering construction. In order to improve the mechanical behaviors of the calcareous sand and reduce the erosion problems caused by extreme rainstorms, an eco-friendly, cost-effective microbial-induced calcium carbonate precipitation (MICP) synergistic fiber reinforcement (FR) modification technology is proposed. The superficial layer of the calcareous sand is modified by spraying process, and the influences of the cementing liquid concentrations (0.5, 1.0, 1.5, 2.0 mol/L) and the fiber contents (0.1, 0.2, 0.3, 0.4%) on the treatment effect are considered. The cementation degree and surface erosion resistance of the calcareous sand under different treatment methods are analyzed by carrying out mini-penetration tests and simulated rainstorm scouring tests combined with electrical conductivity. The results show that: (1) The MICP technology can effectively cement the calcareous sand and improve its mechanical behaviors. The higher the cementing liquid concentration, the higher the calcium carbonate content and the penetration resistance of the samples, and the curing effect with the concentration of 2.0 mol /L is the best; (2) The addition of fiber can significantly improve the cementing effect of MICP, and the fiber content has an important influence on the mechanical behaviors of the microbial solidified samples. The peak penetration resistance first increases and then decreases with the fiber content, and the optimal fiber content is 0.2%; (3) The MICP-treated samples show better erosion resistance under the simulated rainstorm condition, the erosion amount is less than 1/7 of the untreated samples, and the effect is better after adding fiber. MICP-FR synergy can effectively improve the engineering properties of the calcareous sand and play an active role in the island construction and coastal development.

-

0. 引言

土的渗透特性是土重要的工程性质之一,影响着土木工程的施工。目前无黏性土渗透特性的试验研究,多是采用竖向圆柱体模型槽进行,试验中土体受到的水流的作用方向是由下至上的竖直方向,而对于土体承受水平向渗流时土体渗透特性的研究不多[1],渗流方向对土体渗流变形特性的研究还尚未给予足够重视。对土渗流的研究表明,实际施工中渗流的优势方向往往是水平方向,通常土体水平向的渗透性大于竖向,而抵抗水平向渗透破坏的能力低于抵抗竖向渗透破坏的能力[2-6]。

本文针对粉砂竖向和水平向渗透特性研究存有的不足,利用自主设计的实验装置,对粉砂开展竖向和水平向渗流试验,对比分析了两种不同方向渗流场下粉砂的渗透特性。基于室内模拟试验,建立三维离散元与计算流体力学耦合的细观力学模型,对粉砂在竖向和水平向的渗流情况进行分析和计算。通过数值计算结果,对竖向和水平向渗流作用下的粉砂内部接触力、渗流速度及流场的分布规律进行细观分析,将数值模拟与室内试验的结果进行分析、比较。

1. 不同渗流方向下粉砂渗透变形室内试验模拟

1.1 试验仪器和方法

(1)试验仪器

粉砂的竖向渗透变形试验借助实验室自主设计的圆柱形渗流试验仪进行,该装置示意图如图1所示。粉砂水平向渗流渗透变形特性的研究是在自主设计的水平渗流试验装置中进行的,见图2。模型由进水系统,装样区及排水系统3个主要部分组成。进水系统可以通过对进水水头高度的调节自由选择水头加载高度。

(2)试验方法及步骤

粉砂烘干并分层装样。称样烘干24 g取出装样,每10 cm分为一层进行装样;排气饱和。装样完成,分次提升水箱供水高度对试验土样进行饱和,最后一次使水头抬升至与试样顶端齐平,静置24 h;逐级调整水头进行试验。逐级抬升水头高度,对测压管水头高度读数并记录,同时量测渗流量大小,记录试验进程中的渗流现象,直至该级渗流稳定,转入下一级水头;当试验过程中,流量忽然增大,并出现明显的渗流通道,可以认定为试样发生渗透破坏,不再继续加大水头高度,试验完成。

1.2 粉砂竖向和水平向渗流试验结果分析

对粉砂在竖向渗流下的渗透流速受水力梯度影响下的变化规律进行研究,得到渗流速度随水力梯度变化的关系曲线,如图3所示。对粉砂在水平向渗流作用下的临界水力梯度进行研究,结果如图4所示。

由图3得到,在水力梯度

i <0.787时,渗流速度随水力梯度呈近似线性的变化,此时土样处于渗流稳定阶段;当水力梯度为1.1时,渗流速度忽然增大,粉砂颗粒流失量也徒增,此时土体发生渗透变形。图4粉砂在水平向渗流下的变化规律显示:水力梯度小于0.45时,粉砂土渗透流速随着水力梯度的增大呈线性增长,水流清澈,粉砂流出较少。当水力梯度增至0.52时,试样整体的流速瞬间增大,粉砂流出量明显增多且呈持续流失状态,此时粉砂土样内部颗粒运移不再规律,试样开始发生渗透破坏。表1给出粉砂在两种渗流方向下的渗透系数、临界坡降与破坏坡降。粉砂在竖向渗流时的临界水力梯度为0.787,破坏水力梯度为1.10;而水平向渗流中,所能承受的临界水力梯度为0.45。在影响因素诸如种类、级配、密度、孔隙大小等相同的前提下,粉砂竖向渗流的临界水力梯度比水平向高出近44%。由于土体在受到水平向渗流时,平均渗透系数取决于最透水土层的厚度和渗透性;而对于竖向渗流,其平均渗透系数取决于最不透水土层的渗透性。加之,竖向渗流中重力作用与渗流方向一致,会产生对土层的压密作用,使得该渗流方向下的渗透系数小于水平向,而土体能够承受的水头高于水平向的渗流。

表 1 不同渗流方向下粉砂渗透系数、临界坡降和破坏坡降Table 1. Datat of permeability coeffieient of silt, critical slope and failure slope under different seepage directions渗流方向 渗透系数/(10-4 cm·s-1) 临界水力梯度 破坏水力梯度 竖向 6.13 0.787 1.10 水平 6.25 0.450 0.52 2. 不同渗流方向下粉砂渗透变形颗粒流模拟

对于固相颗粒,通过求解运动和动量方程模拟颗粒运动,采用离散元的颗粒流理论进行模拟;对于液相介质,采用均一化流体计算技术模拟其在孔隙中的运动,也就是通过求解平均Navier-Stokes方程模拟孔隙中流体的运动[7-9]。

2.1 数值模型

对粉砂土不同向渗流形态的模拟中,边界条件的界定也略有不同。竖向渗流下,颗粒周边的边界为固壁边界条件,上下为压力边界条件。水平向渗流下,模型的前后和上下边界为固壁边界条件,左右设置为压力边界条件和自由边界条件。生成的土体模型如图5所示。

对于竖向的渗流,按照试验中模型,上覆为自由边界,没有压重。对于水平向的渗流,试样在重力和浮力作用下保持平衡,当作用渗流力后,土中小颗粒将从模型右侧流出,因此在试样右侧设置了相互交叉垂直的线墙,如图6所示。

2.2 数值计算流程

采用PFC3D对流固耦合问题进行计算流程如图7所示。

2.3 数值模拟结果

(1)粉砂土竖向和水平向渗流下渗透变形情况

a)粉砂竖向渗流下的渗透变形情况

图8给出了粉砂在竖向渗流作用下,土样随水力梯度的变化情况。

水力梯度从0.1,0.2,0.3,...,逐级增加,水力梯度施加至0.7时,粉砂几乎无变化;当水力梯度增至0.8时,土样出现从底部被整体抬升的趋势,发生少量细小颗粒流失的现象;水力梯度继续增至1.0时,土体发生了整体的抬升,土体表面颗粒簇发生整体迁移的现象。模拟结果表明,试样的临界水力梯度在0.8左右。

b)粉砂水平向渗流下的渗透变形情况

粉砂土的水平向渗流中水力梯度也是由0.1,0.2,0.3依次逐级抬升,图9给出了粉砂土在水平向渗流下试样随水力梯度变化的情况。

从图9中可以看出,当水力梯度增至0.3时,试样底部细小颗粒也开始发生迁移,水力梯度继续增大至0.4,此时试样发生颗粒成团的流失,土体发生了渗透变形。水力梯度加载至0.5时,土体颗粒发生了更加显著的整体性渗流破坏。根据模拟结果,得到粉砂土水平向渗流的临界水力梯度在0.4左右。

(2)粉砂土竖向和水平向渗流下配位数变化情况分析

土体的配位数表示了颗粒间的接触数,是表达土颗粒间接触情况的参数之一,总配位数是颗粒与颗粒之间以及颗粒与墙之间的平均接触数,反映出试样的压密程度;力学配位数为颗粒与颗粒之间接触数大于2时的颗粒接触数,反映额土骨架的压密程度。图10,11给出了粉砂土在竖向和水平向渗流作用下,配位数随水力梯度的变化情况。

图10,11可以看出,当竖向渗流的水力梯度为0.8,水平向渗流水力梯度为0.4时,土体的两个配位数都发生迅速的下降,说明此时的土体状态发生了较大的变化,即渗透变形发生。图中,总配位数和力学配位数都在随着水力梯度的增大而不断降低,总的配位数较力学配位数下降更快速,幅度也更大。这是由于水力梯度增大,颗粒发生了移动,颗粒的接触数减小,但在水力梯度增加至土体渗透变形前的整个过程中,总配位数下降幅度明显大于力学配位数,说明发生移动的多为小颗粒,小颗粒的运移使土体中接触数减少,随之小颗粒填充至骨架颗粒孔隙间,与大颗粒发生接触,保持了力学配位数的大小。

3. 结论

(1)粉砂在水平向能承受的渗流破坏作用一般低于竖向渗流。

(2)数值模拟结果与模拟试验过程中粉砂的渗流变化过程相符,数值方法所测得的临界水力梯度与试验测得的结果亦较为吻合。

(3)竖向和水平向渗流下,粉砂的总配位数和力学配位数均随着水力梯度的抬升而衰减,当土体发生渗透破坏,土体配位数出现迅速降低。

-

表 1 聚丙烯纤维的物理力学参数

Table 1 Basic physical and mechanical properties of polypropylene fiber

类型 密度ρ/(g·m-³) 直径d/mm 抗拉强度/MPa 弹性模量/MPa 熔点/℃ 燃点/℃ 束装单丝 0.91 0.02~0.048 ≥350 ≥3500 165 590 表 2 试验分组及参数设置

Table 2 Test grouping and parameter setting

试样分组 试样编号 纤维掺量/% 胶结液浓度/(mol·L-1) 对照样 S0 0.0 0.5 A组 S1 0.1 0.5 S2 0.2 0.5 S3 0.3 0.5 S4 0.4 0.5 B组 S5 0.0 0.5 S6 0.0 1.0 S7 0.0 1.5 S8 0.0 2.0 -

[1] 文哲, 段志刚, 李守定, 等. 中国南海岛礁吹填珊瑚砂剪切力学特性[J]. 工程地质学报, 2020, 28(1): 77-84. https://www.cnki.com.cn/Article/CJFDTOTAL-GCDZ202001009.htm WEN Zhe, DUAN Zhi-gang, LI Shou-ding, et al. Shear mechanical properties of dredged coral sands from South China sea, China[J]. Journal of Engineering Geology, 2020, 28(1): 77-84. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GCDZ202001009.htm

[2] 汪稔, 吴文娟. 珊瑚礁岩土工程地质的探索与研究——从事珊瑚礁研究30年[J]. 工程地质学报, 2019, 27(1): 202-207. https://www.cnki.com.cn/Article/CJFDTOTAL-GCDZ201901022.htm WANG Ren, WU Wen-juan. Exploration and research on engineering geological properties of coral reefs——engaged in coral reef research for 30 years[J]. Journal of Engineering Geology, 2019, 27(1): 202-207. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GCDZ201901022.htm

[3] JIANG N J, TANG C S, YIN L Y, et al. Applicability of microbial calcification method for sandy slope surface erosion control[J]. Journal of Materials in Civil Engineering, 2019, 31(11): 04019250. doi: 10.1061/(ASCE)MT.1943-5533.0002897

[4] 胡波, 汪稔, 胡明鉴, 等. 水力吹填砂地基强夯处理试验研究[J]. 岩土力学, 2007, 28(增刊1): 89-92. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2007S1018.htm HU Bo, WANG Ren, HU Ming-jian, et al. Experimental research on dynamic consolidation method of hydraulic filled sand[J]. Rock and Soil Mechanics, 2007, 28(1): 89-92. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2007S1018.htm

[5] OPERSTEIN V, FRYDMAN S. The influence of vegetation on soil strength[J]. Proceedings of the Institution of Civil Engineers-Ground Improvement, 2000, 4(2): 81-89. doi: 10.1680/grim.2000.4.2.81

[6] 钱春香, 王安辉, 王欣. 微生物灌浆加固土体研究进展[J]. 岩土力学, 2015, 36(6): 1537-1548. doi: 10.16285/j.rsm.2015.06.003 QIAN Chun-xiang, WANG An-hui, WANG Xin. Advances of soil improvement with bio-grouting[J]. Rock and Soil Mechanics, 2015, 36(6): 1537-1548. (in Chinese) doi: 10.16285/j.rsm.2015.06.003

[7] 刘汉龙, 肖鹏, 肖杨, 等. MICP胶结钙质砂动力特性试验研究[J]. 岩土工程学报, 2018, 40(1): 38-45. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201801003.htm LIU Han-long, XIAO Peng, XIAO Yang, et al. Dynamic behaviors of MICP-treated calcareous sand in cyclic tests[J]. Chinese Journal of Geotechnical Engineering, 2018, 40(1): 38-45. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201801003.htm

[8] 崔明娟, 郑俊杰, 赖汉江. 颗粒粒径对微生物固化砂土强度影响的试验研究[J]. 岩土力学, 2016(增刊2): 397-402. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2016S2051.htm CUI Ming-juan, ZHENG Jun-jie, LAI Han-jiang. Experimental study of effect of particle size on strength of bio-cemented sand[J]. Rock and Soil Mechanics, 2016(S2): 397-402. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2016S2051.htm

[9] 邵光辉, 冯建挺, 赵志峰, 等. 微生物砂浆防护粉土坡面的强度与抗侵蚀性影响因素分析[J]. 农业工程学报, 2017, 33(11): 141-147. https://www.cnki.com.cn/Article/CJFDTOTAL-NYGU201711017.htm SHAO Guang-hui, FENG Jian-ting, ZHAO Zhi-feng, et al. Influence factor analysis related to strength and anti-erosion stability of silt slope with microbial mortar protective covering[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(11): 141-147. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-NYGU201711017.htm

[10] DEJONG J T, SOGA K, KAVAZANJIAN E, et al. Biogeochemical processes and geotechnical applications: Progress, opportunities and challenges[J]. Géotechnique, 2013, 63(4): 287-301.

[11] 何稼, 楚剑, 刘汉龙, 等. 微生物岩土技术的研究进展[J]. 岩土工程学报, 2016, 38(4): 643-653. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201604010.htm HE Jia, CHU Jian, LIU Han-long, et al. Research advances in biogeotechnologies[J]. Chinese Journal of Geotechnical Engineering, 2016, 38(4): 643-653. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201604010.htm

[12] 方祥位, 申春妮, 楚剑, 等. 微生物沉积碳酸钙固化珊瑚砂的试验研究[J]. 岩土力学, 2015, 36(10): 2773-2779. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201510005.htm FANG Xiang-wei, SHEN Chun-ni, CHU Jian, et al. An experimental study of coral sand enhanced through microbially-induced precipitation of calcium carbonate[J]. Rock and Soil Mechanics, 2015, 36(10): 2773-2779. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201510005.htm

[13] 方祥位, 李晶鑫, 李捷, 等. 珊瑚砂微生物固化体单轴损伤本构模型[J]. 地下空间与工程学报, 2018, 14(5): 93-98. https://www.cnki.com.cn/Article/CJFDTOTAL-BASE201805012.htm FANG Xiang-wei, LI Jing-xin, LI Jie, et al. Damage constitutive model of biocemented coral sand columns under unconfined compression[J]. Chinese Journal of Underground Space and Engineering, 2018, 14(5): 93-98. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BASE201805012.htm

[14] 李捷, 方祥位, 申春妮, 等. 含水率对珊瑚砂微生物固化体力学特性影响研究[J]. 工业建筑, 2016(12): 93-97. https://www.cnki.com.cn/Article/CJFDTOTAL-GYJZ201612019.htm LI Jie, FANG Xiang-wei, SHEN Chun-ni, et al. Influence of moisture content on mechanical properties of biocemented coral sand columns[J]. Industrial Construction, 2016(12): 93-97. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GYJZ201612019.htm

[15] 马瑞男, 郭红仙, 程晓辉, 等. 微生物拌和加固钙质砂渗透特性试验研究[J]. 岩土力学, 2018, 39(增刊2): 217-223. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2018S2031.htm MA Rui-nan, GUO Hong-xian, CHENG Xiao-hui, et al. Permeability experiment study of calcareous sand treated by microbially induced carbonate precipitation using mixing methods[J]. Rock and Soil Mechanics, 2018, 39(S2): 217-223. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2018S2031.htm

[16] 欧益希, 方祥位, 张楠, 等. 溶液盐度对微生物固化珊瑚砂的影响[J]. 后勤工程学院学报, 2016, 32(1): 78-82. https://www.cnki.com.cn/Article/CJFDTOTAL-HQGC201601015.htm OU Yi-xi, FANG Xiang-wei, ZHANG Nan, et al. Influence of solution salinity on microbial biocementation of coral sand[J]. Journal of Logistical Engineering University, 2016, 32(1): 78-82. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HQGC201601015.htm

[17] 彭劼, 田艳梅, 杨建贵. 海水环境下MICP加固珊瑚砂试验[J]. 水利水电科技进展, 2019, 39(1): 62-66. https://www.cnki.com.cn/Article/CJFDTOTAL-SLSD201901011.htm PENG Jie, TIAN Yan-mei, YANG Jian-gui. Experiments of coral sand reinforcement using MICP in seawater environment[J]. Advances in Science and Technology of Water Resources, 2019, 39(1): 62-66. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-SLSD201901011.htm

[18] 谢约翰, 唐朝生, 尹黎阳, 等. 纤维加筋微生物固化砂土的力学特性[J]. 岩土工程学报, 2019, 41(4): 675-682. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201904014.htm XIE Yue-han, TANG Chao-sheng, YIN Li-yang, et al. Mechanical behavior of microbial-induced calcite precipitation (MICP)-treated soil with fiber reinforcement[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(4): 675-682. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201904014.htm

[19] 吴洋, 练继建, 闫玥, 等. 巴氏芽孢八叠球菌及相关微生物的生物矿化的分子机理与应用[J]. 中国生物工程杂志, 2017, 37(8): 96-103. https://www.cnki.com.cn/Article/CJFDTOTAL-SWGJ201708014.htm WU Yang, LIAN Ji-jian, YAN Yue, et al. Mechanism and applications of bio-mineralization induced by sporosarcinapasteurii and related microorganisms[J]. China Biotechnology, 2017, 37(8): 96-103. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-SWGJ201708014.htm

[20] WANG D Y, TANG C S, CUI Y J, SHI B, LI J. Effects of wetting-drying cycles on soil strength profile of a silty clay in micro-penetrometer tests[J]. Engineering Geology, 2016, 206: 60-70.

[21] 施斌, 刘志彬, 蔡奕. 超微型贯入仪的研制及其应用[J]. 岩土力学, 2005(8): 1211-1215. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX200508006.htm SHI Bin, LIU Zhi-bin, CAI Yi. Development of the super mini-penetrometer and its application[J]. Rock and Soil Mechanics, 2005(8): 1211-1215. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX200508006.htm

[22] RÖMKENS M J M, HELMING K, PRASAD S N. Soil erosion under different rainfall intensities, surface roughness, and soil water regimes[J]. Catena, 2002, 46(2/3): 103-123.

[23] 金宗川. 钙质砂的休止角研究与工程应用[J]. 岩土力学, 2018, 39(7): 2583-2590. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201807031.htm JIN Zong-chuan. Study of natural repose angle of calcareous sand and engineering application[J]. Rock and Soil Mechanics, 2018, 39(7): 2583-2590. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201807031.htm

[24] 李贤, 汪时机, 何丙辉, 等. 土体适用MICP技术的渗透特性条件研究[J]. 岩土力学, 2019, 40(8): 2956-2964, 2974. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201908010.htm LI Xian, WANG Shi-ji, HE Bing-hui, et al. Permeability condition of soil suitable for MICP method[J]. Rock and Soil Mechanics, 2019, 40(8): 2956-2964, 2974. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201908010.htm

[25] LI M D, LI L, OGBONNAYA U, et al. Influence of fiber addition on mechanical properties of MICP-treated sand[J]. Journal of Materials in Civil Engineering, 2016, 28(4): 04015166.

[26] TANG C S, SHI B, GAO W, CHEN F, CAI Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil[J]. Geotextiles & Geomembranes, 2007, 25(3): 194-202.

[27] TANG C S, SHI B, ZHAO L Z. Interfacial shear strength of fiber reinforced soil[J]. Geotextiles & Geomembranes, 2010, 28(1): 54-62.

-

期刊类型引用(4)

1. 应宏伟,陈雨,王阳扬,刘冠. 含碎石芯软黏土复合试样大三轴试验研究. 湖南大学学报(自然科学版). 2024(11): 104-114 .  百度学术

百度学术

2. 邱俊峰,叶晨峰,陈峰,郑铖杰. 镍铁渣粉水泥固化砂土剪切强度与应力应变关系研究. 湖南文理学院学报(自然科学版). 2023(02): 78-82+95 .  百度学术

百度学术

3. 殷天军,宁华宇,寇晓强. 深中通道沉管基础水下深层水泥搅拌桩应用全过程探讨. 中国港湾建设. 2022(07): 11-16 .  百度学术

百度学术

4. 张振,郑文强,叶观宝,陈勇. 循环荷载下水泥土桩复合单元体变形特性及其地基长期沉降计算方法. 中国公路学报. 2022(11): 21-29 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: