Spatiotemporal evolution of microbial-induced calcium carbonate precipitation based on microfluidics

-

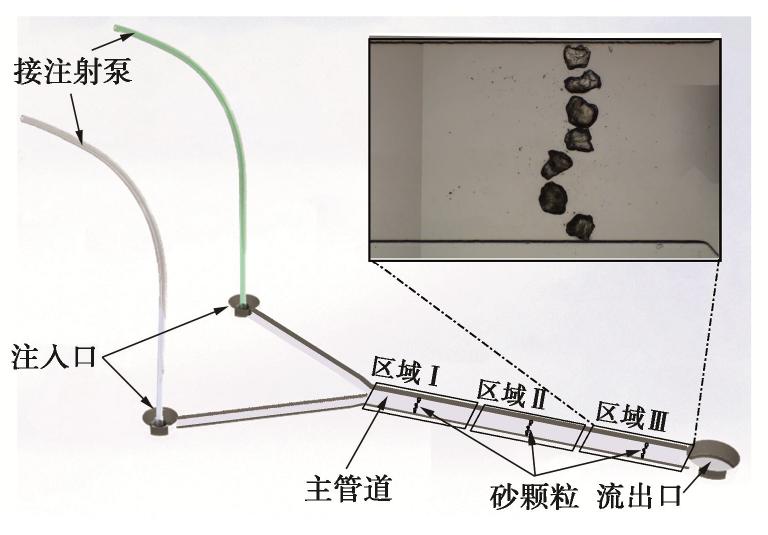

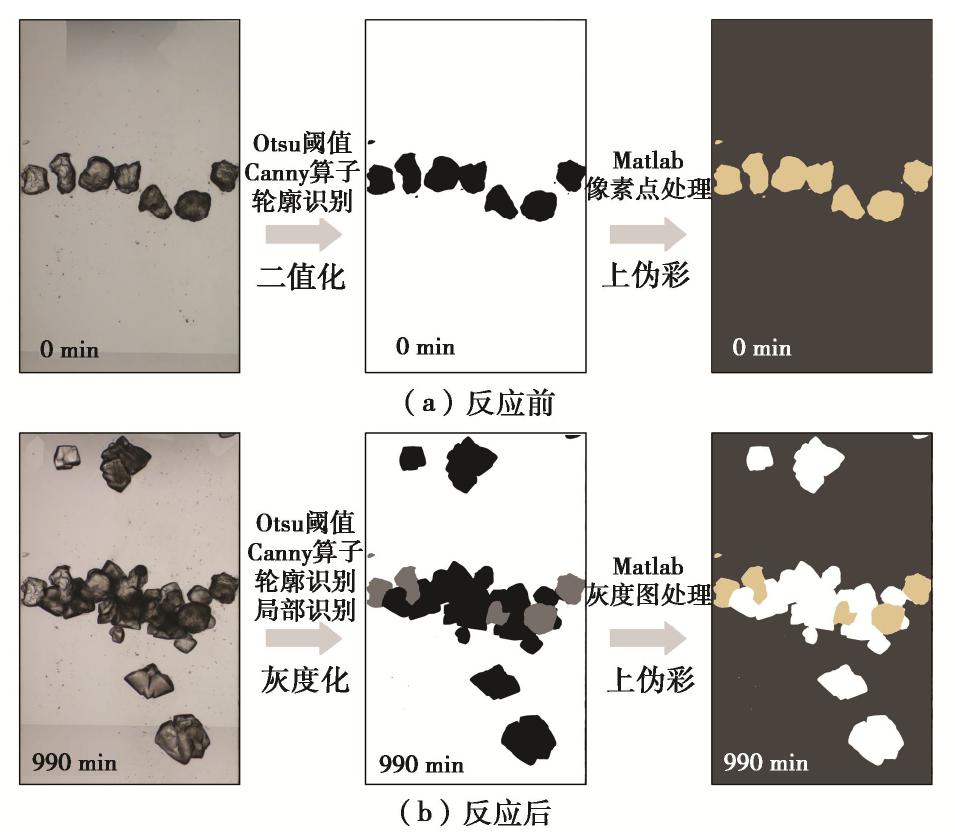

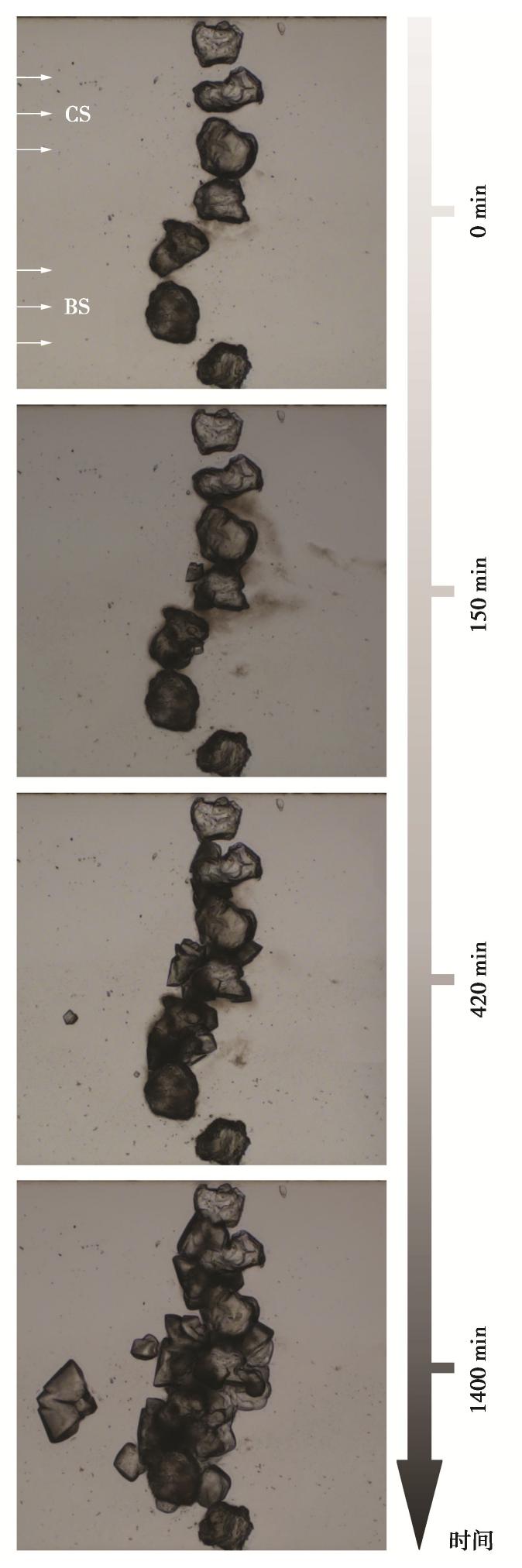

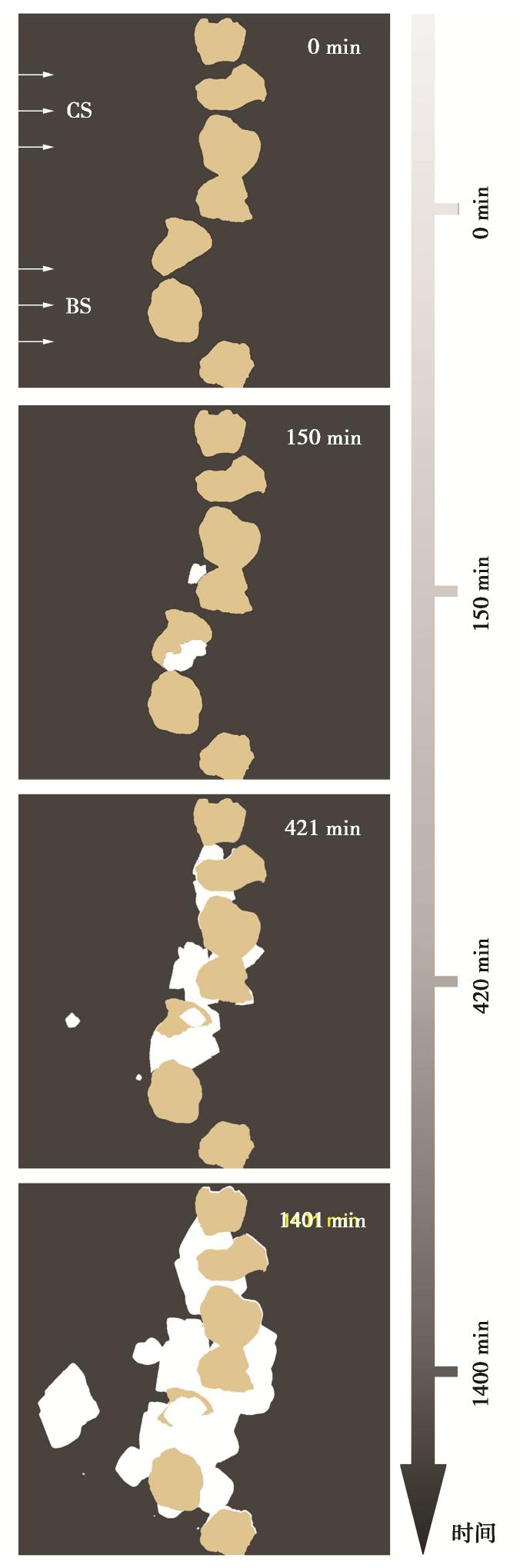

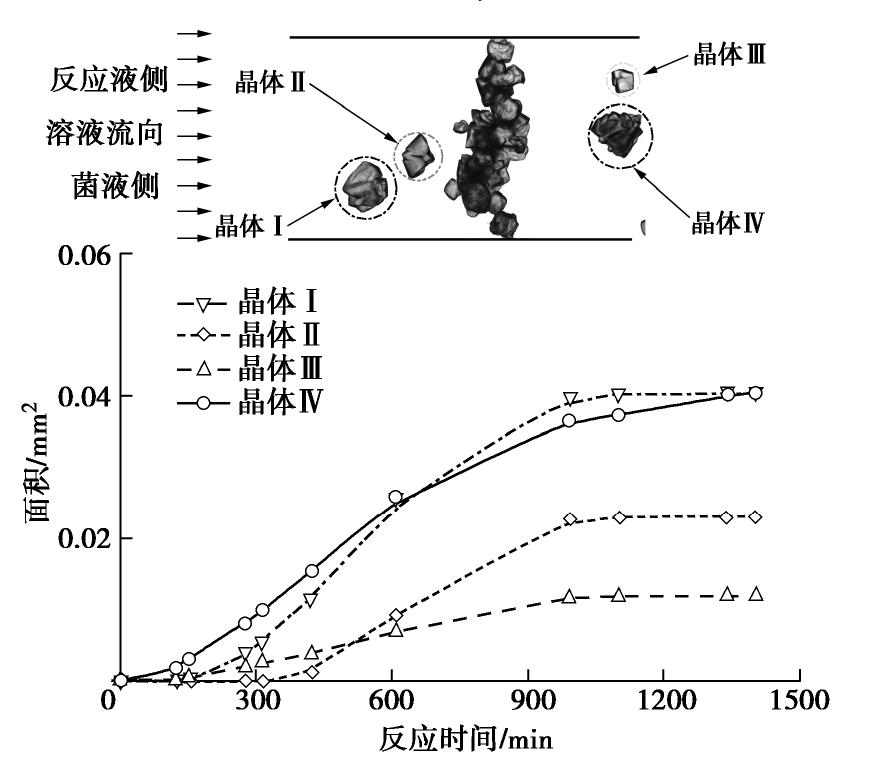

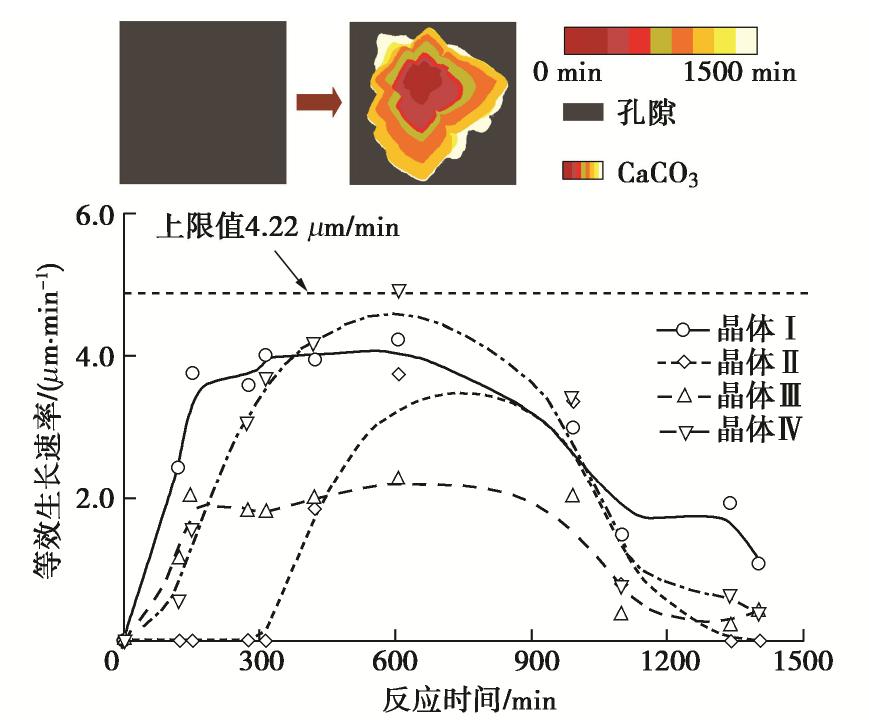

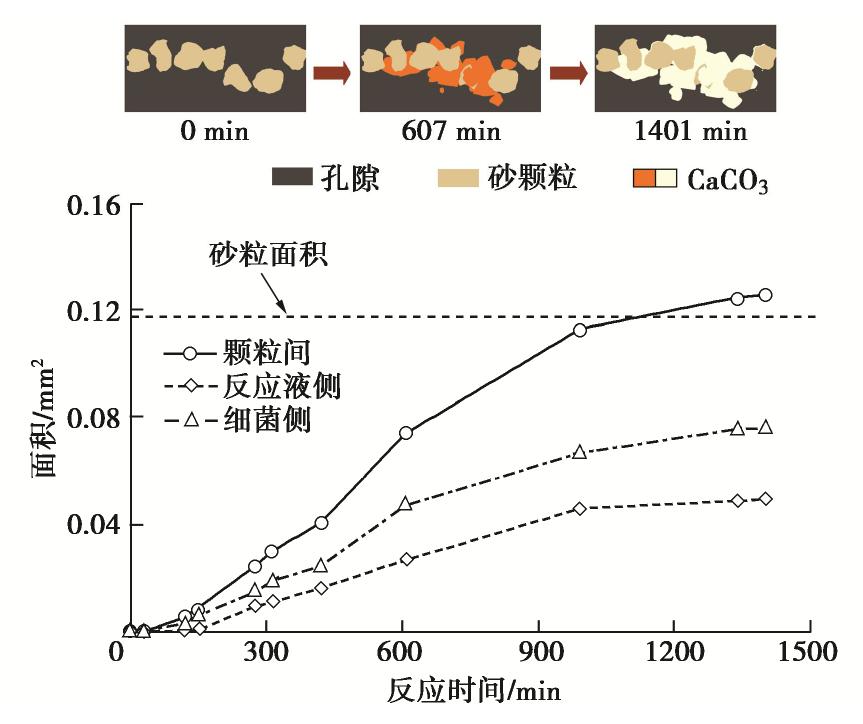

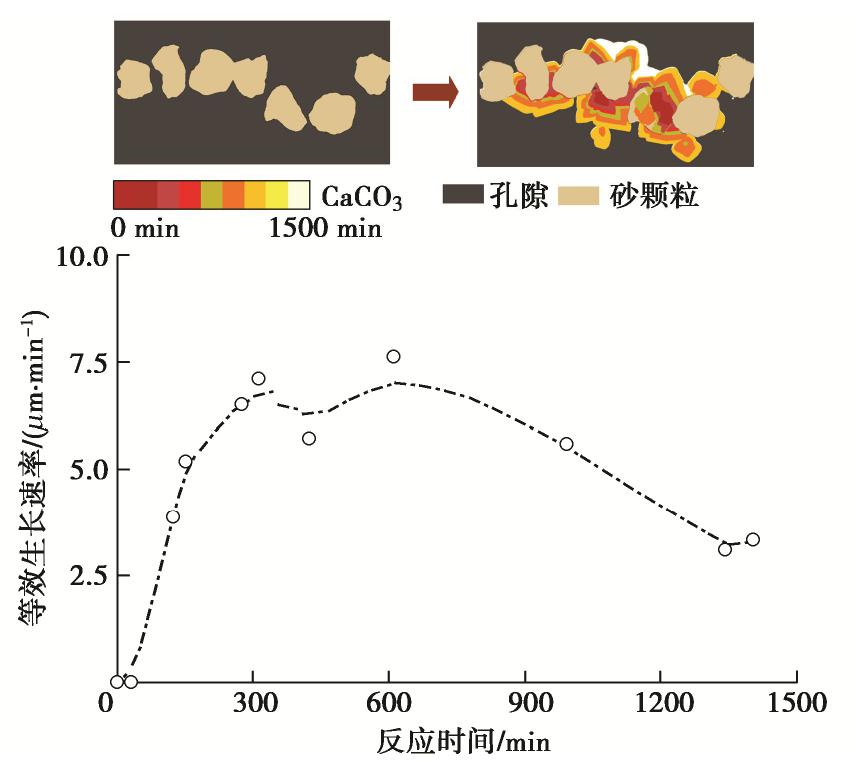

摘要: 微生物矿化沉积是近年来的热门研究课题,然而人们对其时空演化过程的认识目前稍显不足。设计了具有大小孔隙的概念化微流控芯片,并利用微生物加固可视化系统对微生物矿化沉积的时空演化过程进行研究。提出了一种图像处理方法,该方法能够对沉积过程中的碳酸钙进行识别和计算,从而对微生物矿化沉积的时空演化过程进行量化研究。结果表明孔隙空间结构对碳酸钙晶体具有一定的调控作用,管道大孔隙中碳酸钙以单晶的形式存在,而砂颗粒间小孔隙中碳酸钙以聚合体的方式渐进生长并表现出3个不同的生长过程。无论单晶还是聚合体碳酸钙,它们的生长速率均随反应时间先增加后逐渐降低,碳酸钙晶体面积的等效半径增长速率最大为4.22 μm/min。研究结果有望验证孔隙尺度微生物矿化沉积模拟,为现场工程应用提供参考。Abstract: The microbial-induced calcium carbonate precipitation (MICP) is a hot research topic in recent years, however, the understanding of its spatiotemporal evolution is still insufficient. This paper aims to investigate the spatiotemporal evolution process by designing a conceptual microfluidic chip within large and small pores and using a visualized experimental platform. An image-processing method is proposed to distinguish the calcium carbonate and measure its areas during the precipitation process, which allows the quantitative study on the spatiotemporal evolution process of MICP. The results show that the pore structures are involved in regulation of crystallization of the calcium carbonate. The calcium carbonate in the large pores of the channel exhibit as a single crystal, while those in the small pores between the sand particles show asymptotic growth in the form of aggregates and exhibit three different growth processes. Regardless of single crystal or crystalline aggregates, the growth rate of the calcium carbonate first increases and then gradually decreases with the increasing reaction time. The maximum growth rate is 4.22 μm/min with respect of the equivalent radius of the calcium carbonate crystals. This study is expected to benchmark the pore-scale modeling of biomineralization and provide reference for field practices.

-

Keywords:

- biomineralization /

- microfluidics /

- calcium carbonate /

- growth rate /

- MICP

-

0. 引言

振杆密实法是一种新兴的可液化地基与黄土地基处理方法,该法通过振动杆在沉杆过程中与土体发生共振,土体吸收振动能量并进一步密实[1-2]。Chow[3]、程远等[4]分别介绍了振杆密实法在美国、中国等地可液化地基中的应用,该方法无需填料,施工简便,取得了显著效果。已有研究表明,振杆密实法的处理效果与施工参数密切相关。Massarsch等[5]应用谱分析原理求得振杆-土的共振频率以低频为主(≤20 Hz),不同土性之间略有差异;程远等[6]研究发现粉土地基的最佳振动频率为17 Hz。Brown等[7]、Wallays等[8]基于静力触探、地表沉降测量等原位测试方法对不同振杆形状的处理效果进行了对比,发现十字杆的处理效果最好,Y字杆次之,Terra杆最差。Janes[9]建议采用振杆密实法进行地基处理时需要进行不同振点间距现场试验以确定合适间距。Massarsch等[10]研究表明大间距长留振的处理效果不如小间距短留振。

上述研究成果主要应用于可液化地基,振杆密实法在湿陷性黄土地基中采用上述施工参数是否适用仍不明确。本文利用自主研发的振杆密实施工设备在湿陷性黄土地基的应用开展现场试验研究,探究了振动频率、喷气压力、钻头形式、振点间距对施工效率和处理效果的影响。研究成果可为振杆密实法在湿陷性黄土地基中的进一步应用提供技术参考。

1. 试验方案与场地工程概况

1.1 试验设备

采用自主研发的适用于黄土地基的智能化振杆密实施工设备进行现场试验,该设备主要包括①振动系统;②喷气系统;③智能化控制系统;④附属机构系统4部分组成[2]。施工设备详细参数见表1。

表 1 施工设备主要参数Table 1. Main parameters of construction equipments电机功率/kW 激振力/kN 喷气压力/MPa 可调频率/Hz 深度/m 振杆直径/m 90 530 0.5~1.2 0~30 ≤15 0.7 1.2 试验方案

振杆密实法的处理效果受施工设备、土层参数和施工工艺共同影响,其施工参数主要有:振动频率、钻头形式、喷气压力、振点间距。基于此,在试验场地内开展振杆密实单点试验和群点试验:

(1)单点试验:通过试振不同的振动频率和组合钻头形式对湿陷性黄土地基进行处理,对比施工效率和振孔尺寸,寻找最优施工参数,为群点试验提供参考。

(2)群点试验:在单点试验的基础上,选取一定的振动参数对区域进行集中处理,群点试验由27个单点组成,呈正三角形布置。通过改变不同的喷气压力与振点间距,探究其对加固效果的影响,群点试验处理7 d后进行静力触探试验,测试地基承载力变化,静力触探试验每个振区测3个点,分别为振点中心,两点之间,三点形心。

1.3 场地工程概况

本次试验场地位于中兰客专靖远县高铁站场坪区附近,场地内地层岩性主要为第四系全新统冲洪积层(Q4al+pl)砂质黄土,含水率为7.2%~11.5%,孔隙比0.975~1.121,干密度为1.27~1.36 g/cm3,具自重湿陷性,湿陷系数δs=0.010~0.087,自重湿陷系数δzs=0.005~0.024,湿陷性土层厚21~37.3 m,需对其进行地基处理,设计处理深度为8 m。

2. 振杆密实法施工参数分析

2.1 振动频率的影响

参考土体的共振频率,设计了不同振动频率下(14,15,16,17 Hz)下的单点振动试验。图1(a)为不同振动频率下施工速率或振孔参数柱状图。由图1(a)可以看出,随着振动频率的增大,沉杆速率、提升速率先增大后减小,在16 Hz处有最大值。

此外,振孔深度随振动频率的变化趋势与施工速率相似,在16 Hz处有最大值,振孔深度为2.5 m。而不同振动频率下的振孔直径基本相同,为0.7 m,14 Hz下略低,为0.65 m。如果把振杆-地基土看成一个共振体,当振动沉杆的振动频率接近于处理土体的固有频率时,振杆与土体产生强迫振动,此时共振体的振幅达到最大,沉杆过程功率消耗最低,施工速率最快,密实效率达到最佳。因此判断该场地的湿陷性黄土地基,振杆-土的共振频率为16 Hz。

2.2 组合钻头形式的影响

在可液化地基处理中,振杆形状对处理效果的影响显著。然而通过现场试振发现,黄土的强结构性使得钻头形式比振杆形式对其影响更大。因此设计了3种组合形式的钻头(图2)进行单点试振试验,得到不同组合钻头形式的施工速率与振孔参数柱状图如图1(b)所示。

由图1(b)可以看出,相对于普通钻头,3种组合钻头的施工速率和振孔深度均有明显提升,施工速率提高约100%~200%,振孔深度增大约50%,这主要是因为普通钻头在沉杆过程中翼片间会发生黏结堵塞现象,使得钻头阻力增大,沉杆困难,甚至无法打至设计深度。而组合钻头的翼片间相互错开,在刺入土体过程中可以将黏结在翼片之间的土体破坏,减少黏结现象,从而有效提高沉杆速率。此外,对比不同形式的组合钻头可以看出,A型钻头的沉杆速率、提升速率、振孔深度均最大,因此判断在该场地条件下,这种形式的组合钻头最适宜。不同钻头的振孔直径均为0.7 m,表明振孔直径与振杆直径有关,与钻头形式无关。

2.3 喷气压力的影响

为了探究喷气压力对加固效果的影响,分别设置不同的喷气压力(0.6,0.8,1.0 MPa),基于单点试验结果,控制振动频率为16 Hz,钻头形式为A型,振点间距为1.2 m,进行了群点试验。

不同测点处锥尖阻力与侧壁阻力随深度变化的关系曲线如图3所示。可以看出,不论气压大小,两点之间、三点形心处的锥尖阻力和侧壁阻力较处理前提升约150%~250%,表明振杆密实法有效提高了孔间土的强度及密实度。在两点之间,0.6 MPa处理区的锥尖阻力和侧壁阻力均为最大,1.0 MPa处理区最小,表明小气压对两点之间强度增长有益。在三点之间,1.0 MPa处理区的锥尖阻力和侧壁阻力最大,0.6 MPa与0.8 MPa的试验数值相对较小,原因在于1.0 MPa的气压加上留振作用破坏了0.4 m厚的两点间的土层,且未经有效压实。综合对比3个不同气压处理区的静力触探试验结果发现,喷气压力为0.8 MPa时两点之间、三点形心处较未加固区都有较大提高,且分布较均匀,可推荐作为施工参数使用。

2.4 振点间距的影响

分别设置不同振点间距(1.1,1.2,1.4 m),控制振动频率为16 Hz,钻头形式为A型,喷气压力为0.8 MPa进行现场群点试验。试验发现,当振点间距为1.1 m时,由于间距过小,振点间易发生串孔现象,导致振杆倾斜,无法形成振坑。

不同间距下锥尖阻力及侧壁阻力随深度变化曲线如图4所示。可以看出,相对于处理前,处理后的振区的锥尖阻力明显提升约200%~300%。对比不同振点间距的锥尖阻力可以发现,在振点中心处,1.2 m处理区与1.4 m处理区的锥尖阻力比较接近,表明振点间距对振孔中心处的强度影响不大。在两点中之间、三点形心处,1.2 m处理区的锥尖阻力和侧壁阻力明显比1.4 m处理区的大约50%,表明振点间距越小,加固效果越显著。振杆密实法对地基土的加固是依靠振动能量,而振动能量是以振动波的形式传递,波的传播随距离增大逐渐衰减,振点间距越小,振动波的叠加效应也越明显。此外,由于是群点试验,振点间距越小,挤密效果亦更好,但振点间距过小容易造成串孔现象。在该场地条件下,参照《铁路工程地质原位测试规程》(TB 10018—2018)中天然地基基本承载力经验公式,计算得到该场地设计承载力(180 kPa)对应的锥尖阻力约为3.2 MPa。1.2 m和1.4 m振点间距处理后的地基土,除表层土体外,均达到设计指标。

3. 结论

本文对振杆密实法处理湿陷性黄土地基的施工参数开展了现场试验研究,主要结论如下:

(1)在本文的场地条件下,振杆密实法处理湿陷性黄土的最优振动频率为16 Hz,该频率下施工速率和密实效果最佳。

(2)黄土的强结构性使得钻头形式比振杆形式对其施工影响更为显著。设计了几种不同的组合钻头,其中A型钻头能防止钻头处的土体黏结,进而提高施工效率。

(3)提出了气动辅助振杆密实的施工方式,基于静力触探试验对不同喷气压力下的处理效果进行了评价。分析结果表明0.8 MPa气压下土体强度提升明显,且静力触探曲线较为均匀,可参考作为施工参数。

(4)不同振点间距的群点试验结果表明,振杆密实法处理后的湿陷性黄土地基锥尖阻力和侧壁阻力提升约200%~300%。振点间距越小,加固效果越显著,但振点间距过小容易造成串孔现象,以1.2~1.4 m为宜。

-

-

[1] SIGEL A, SIGEL H, SIGEL RKO. Biomineralization: From Nature to Application[M]. Chichester: John Wiley & Sons Ltd, 2008.

[2] TANG C-S, YIN L-Y, JIANG N-J, et al. Factors affecting the performance of microbial-induced carbonate precipitation (MICP) treated soil: a review[J]. Environmental Earth Sciences, 2020, 79(5): 24.

[3] JROUNDI F, SCHIRO M, RUIZ-AGUDO E, et al. Protection and consolidation of stone heritage by self-inoculation with indigenous carbonatogenic bacterial communities[J]. Nature Communications, 2017, 8(1): 279. doi: 10.1038/s41467-017-00372-3

[4] QIAN C X, REN L F, XUE B, et al. Bio-mineralization on cement-based materials consuming CO2 from atmosphere[J]. Construction and Building Materials, 2016, 106: 126-132. doi: 10.1016/j.conbuildmat.2015.10.105

[5] 谢约翰, 唐朝生, 尹黎阳, 等. 纤维加筋微生物固化砂土的力学特性[J]. 岩土工程学报, 2019, 41(4): 675-682. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201904014.htm XIE Yue-han, TANG Chao-sheng, YIN Li-yang, et al. Mechanical behavior of microbial-induced calcite precipitation (MICP)- treated soil with fiber reinforcement[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(4): 675-682. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201904014.htm

[6] 方祥位, 申春妮, 楚剑, 等. 微生物沉积碳酸钙固化珊瑚砂的试验研究[J]. 岩土力学, 2015, 36(10): 2773-2779. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201510005.htm FANG Xiang-wei, SHEN Chun-ni, CHU Jian, et al. An experimental study of coral sand enhanced through microbially-induced precipitation of calcium carbonate[J]. Rock and Soil Mechanics, 2015, 36(10): 2773-2779. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201510005.htm

[7] ACHAL V, PAN X, LEE D J, et al. Remediation of Cr(VI) from chromium slag by biocementation[J]. Chemosphere, 2013, 93(7): 1352-1358. doi: 10.1016/j.chemosphere.2013.08.008

[8] LI M, CHENG X, GUO H, et al. Biomineralization of carbonate by terrabacter tumescens for heavy metal removal and biogrouting applications[J]. Journal of Environmental Engineering, 2016, 142(9): C4015005. doi: 10.1061/(ASCE)EE.1943-7870.0000970

[9] ZHANG W, JU Y, ZONG Y, et al. In situ real-time study on dynamics of microbially induced calcium carbonate precipitation at a single-cell level[J]. Environmental Science & Technology, 2018, 52(16): 9266-9276.

[10] HARRIS D, UMMADI J G, THURBER A R, et al. Real-time monitoring of calcification process by Sporosarcina pasteurii biofilm[J]. The Analyst, 2016, 141(10): 2887-2895. doi: 10.1039/C6AN00007J

[11] ZAMBARE N, LAUCHNOR E G, GERLACH R. Controlling the distribution of microbially precipitated calcium carbonate in radial flow environments[J]. Environmental Science & Technology, 2019, 53(10): 5916-5925.

[12] WANG Y, SOGA K, DEJONG J T, et al. Microscale visualization of microbial-induced calcium carbonate precipitation processes[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2019, 145(9): 04019045. doi: 10.1061/(ASCE)GT.1943-5606.0002079

[13] XIAO Y, CHEN H, STUEDLEIN A W, et al. Restraint of particle breakage by biotreatment method[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2020, 146(11): 04020123. doi: 10.1061/(ASCE)GT.1943-5606.0002384

[14] DEJONG J T, FRITZGES M B, NÜSSLEIN K. Microbially induced cementation to control sand response to undrained shear[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2006, 132(11): 1381-1392. doi: 10.1061/(ASCE)1090-0241(2006)132:11(1381)

[15] CHU J, IVANOV V, STABNIKOV V, et al. Microbial method for construction of an aquaculture pond in sand[J]. Géotechnique, 2013, 63(10): 871-875. doi: 10.1680/geot.SIP13.P.007

[16] 李贤, 汪时机, 何丙辉, 等. 土体适用micp技术的渗透特性条件研究[J]. 岩土力学, 2019, 40(8): 2956-2964, 2974. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201908010.htm LI Xian, WANG Shi-ji, HE Bing-hui, et al. Permeability condition of soil suitable for MICP method[J]. Rock and Soil Mechanics, 2020, 40(8): 2956-2964, 2974. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201908010.htm

[17] XIAO Y, HE X, EVANS T M, et al. Unconfined compressive and splitting tensile strength of basalt fiber-reinforced biocemented sand[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2019, 145(9): 04019048. doi: 10.1061/(ASCE)GT.1943-5606.0002108

[18] 李驰, 王硕, 王燕星, 等. 沙漠微生物矿化覆膜及其稳定性的现场试验研究[J]. 岩土力学, 2019, 40(4): 1291-1298. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201904007.htm LI Chi, WANG Shuo, WANG Yan-xing, et al. Field experimental study on stability of bio-mineralization crust in the desert[J]. Rock and Soil Mechanics, 2019, 40(4): 1291-1298. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201904007.htm

[19] 谈叶飞, 郭张军, 陈鸿杰, 等. 微生物追踪固结技术在堤防防渗中的应用[J]. 河海大学学报(自然科学版), 2018, 46(6): 521-526. https://www.cnki.com.cn/Article/CJFDTOTAL-HHDX201806009.htm TAN Ye-fei, GUO Zhang-jun, CHEN Hong-jie, et al. Study on application of microbial tracing consolidation technology in the seepage prevention of earth bank[J]. Journal of Hohai University (Natural Sciences), 2018, 46(6): 521-526. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HHDX201806009.htm

[20] 刘汉龙, 马国梁, 肖杨, 等. 微生物加固岛礁地基现场试验研究[J]. 地基处理, 2019, 1(1): 26-31. https://www.cnki.com.cn/Article/CJFDTOTAL-DJCL201901007.htm LIU Han-long, MA Guo-liang, XIAO Yang, et al. In situ experimental research on calcareous foundation stabilization using MICP technique on the reclaimed coral reef islands[J]. Chinese Ground Improvement, 2019, 1(1): 26-31. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-DJCL201901007.htm

[21] 彭劼, 温智力, 刘志明, 等. 微生物诱导碳酸钙沉积加固有机质黏土的试验研究[J]. 岩土工程学报, 2019, 41(4): 733-740. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201904022.htm PENG Jie, WEN Zhi-li, LIU Zhi-ming, et al. Experimental research on MICP-treated organic clay[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(4): 733-740. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201904022.htm

[22] 欧孝夺, 莫鹏, 江杰, 等. 生石灰与微生物共同固化过湿性铝尾黏土试验研究[J]. 岩土工程学报, 2020, 42(4): 624-631. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202004007.htm OU Xiao-duo, MO Peng, JIANG jie, et al. Experimental study on solidification of bauxite tailing clay with quicklime and microorganism[J]. Chinese Journal of Geotechnical Engineering, 2020, 42(4): 624-631. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202004007.htm

[23] 桂跃, 吴承坤, 刘颖伸, 等. 利用微生物技术改良泥炭土工程性质试验研究[J]. 岩土工程学报, 2020, 42(2): 269-278. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202002011.htm GUI Yue, WU Cheng-kun, LIU Ying-shen, et al. Improving engineering properties of peaty soil by biogeotechnology[J]. Chinese Journal of Geotechnical Engineering, 2020, 42(2): 269-278. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202002011.htm

[24] 黄涛, 方祥位, 张伟, 等. 活性氧化镁-微生物固化黄土试验研究[J]. 岩土力学, 2020, 41(10): 3300-3306, 3316. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202010015.htm HUANG Tao, FANG Xiang-wei, ZHANG Wei, et al. Study of effect of chemical treatment on strength of bio-cemented sand[J]. Rock and Soil Mechanics, 2020, 41(10): 3300-3306, 3316. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202010015.htm

[25] 马国梁, 何想, 路桦铭, 等. 高岭土微粒固载成核微生物固化粗砂强度[J]. 岩土工程学报, 2020, 43(2): 290-299. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202102011.htm MA Guo-liang, HE Xiang, LU Hua-ming, et al. Strength of biocemented coarse sand with kaolin micro-particle improved nucleation[J]. Chinese Journal of Geotechnical Engineering, 2020, 43(2): 290-299. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202102011.htm

[26] 刘汉龙, 肖鹏, 肖杨, 等. MICP胶结钙质砂动力特性试验研究[J]. 岩土工程学报, 2018, 40(1): 38-45. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201801003.htm LIU Han-long, XIAO Peng, XIAO Yang, et al. Dynamic behaviors of MICP-treated calcareous sand in cyclic tests[J]. Chinese Journal of Geotechnical Engineering, 2018, 40(1): 38-45. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201801003.htm

[27] 吴敏, 高玉峰, 何稼, 等. 大豆脲酶诱导碳酸钙沉积与黄原胶联合防风固沙室内试验研究[J]. 岩土工程学报, 2020, 42(10): 1914-1921. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202010023.htm WU Min, GAO Yu-feng, HE Jia, et al. Laboratory study on use of soybean urease-induced calcium carbonate precipitation with xanthan gum for stabilization of desert sand against wind erosion[J]. Chinese Journal of Geotechnical Engineering, 2020, 42(10): 1914-1921. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202010023.htm

[28] 刘璐, 沈扬, 刘汉龙, 等. 微生物胶结在防治堤坝破坏中的应用研究[J]. 岩土力学, 2016, 37(12): 3410-3416. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201612009.htm LIU Lu, SHEN Yang, LIU Han-long, et al. Study of effect of chemical treatment on strength of bio-cemented sand[J]. Rock and Soil Mechanics, 2016, 12(12): 3410-3416. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201612009.htm

[29] XIAO Y, STUEDLEIN A W, RAN J Y, et al. Effect of particle shape on strength and stiffness of biocemented glass beads[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2019, 145(11): 06019016.

[30] XIAO Y, STUEDLEIN AW, PAN Z, et al. Toe bearing capacity of precast concrete piles through biogrouting improvement[J]. Journal of Geotechnical and Geo- environmental Engineering, 2020, 146(12): 06020026.

[31] XIAO P, LIU H L, STUEDLEIN A W, et al. Effect of relative density and biocementation on cyclic response of calcareous sand[J]. Canadian Geotechnical Journal, 2019, 56(12): 1849-1862.

[32] XIAO Y, ZHAO C, SUN Y, et al. Compression behavior of MICP-treated sand with various gradations[J]. Acta Geotechnica, 2021, 16(5): 1391-1400.

[33] MARZIN T, DESVAGES B, CREPPY A, et al. Using microfluidic set-up to determine the adsorption rate of sporosarcina pasteurii bacteria on sandstone[J]. Transport in Porous Media, 2020, 132(2): 283-297.

[34] SCHUSZTER G, BRAU F, DE WIT A. Calcium carbonate mineralization in a confined geometry[J]. Environmental Science & Technology Letters, 2016, 3(4): 156-159.

[35] WANG Y Z, SOGA K, DEJONG J T, et al. A microfluidic chip and its use in characterising the particle-scale behaviour of microbial-induced calcium carbonate precipitation (MICP)[J]. Geotechnique, 2019, 69(12): 1086-1094.

[36] 何想, 马国梁, 汪杨, 等. 基于微流控芯片技术的微生物加固可视化研究[J]. 岩土工程学报, 2020, 42(6): 1005-1012. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202006005.htm HE Xiang, MA Guo-liang, WANG Yang, et al. Visualization investigation of bio-cementation process based on microfluidics[J]. Chinese Journal of Geotechnical Engineering, 2020, 42(6): 1005-1012. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202006005.htm

[37] HU R, WAN J M, KIM Y, et al. Wettability impact on supercritical co2 capillary trapping: Pore-scale visualization and quantification[J]. Water Resources Research, 2017, 53(8): 6377-6394.

[38] FANIZZA MF, YOON H, ZHANG C, et al. Pore-scale evaluation of uranyl phosphate precipitation in a model groundwater system[J]. Water Resources Research, 2013, 49(2): 874-890.

[39] KIM DH, MAHABADI N, JANG J, et al. Assessing the kinetics and pore-scale characteristics of biological calcium carbonate precipitation in porous media using a microfluidic chip experiment[J]. Water Resources Research, 2020, 56(2): e2019WR025420.

[40] TAYLOR H F, O'SULLIVAN C, SIM W W. Geometric and hydraulic void constrictions in granular media[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2016, 142(11): 04016057.

[41] CHENG L, CORD-RUWISCH R, SHAHIN M A. Cementation of sand soil by microbially induced calcite precipitation at various degrees of saturation[J]. Canadian Geotechnical Journal, 2013, 50(1): 81-90.

[42] GAO Y F, TANG X Y, CHU J, et al. Microbially induced calcite precipitation for seepage control in sandy soil[J]. Geomicrobiology Journal, 2019, 36(4): 366-375.

[43] BLAUW M, LAMBERT J, LATIL M N. Biosealing: A method for in situ sealing of leakages[C]//International Symposium on Ground Improvement Technologies and Case Histories (ISGI09), 2009, Singapore.

[44] WOEHL T J, EVANS J E, ARSLAN I, et al. Direct in situ determination of the mechanisms controlling nanoparticle nucleation and growth[J]. ACS Nano, 2012, 6(10): 8599-8610.

[45] POUGET E M, BOMANS P H H, GOOS J A C M, et al. The initial stages of template-controlled CaCO3 formation revealed by cryo-TEM[J]. Science, 2009, 323(5920): 1455-1458.

[46] DUPRAZ S, PARMENTIER M, MÉNEZ B, et al. Experimental and numerical modeling of bacterially induced ph increase and calcite precipitation in saline aquifers[J]. Chemical Geology, 2009, 265(1/2): 44-53.

[47] EBIGBO A, PHILLIPS A, GERLACH R, et al. Darcy-scale modeling of microbially induced carbonate mineral precipitation in sand columns[J]. Water Resources Research, 2012, 48(7): 17.

[48] QIN C Z, HASSANIZADEH S M, EBIGBO A. Pore-scale network modeling of microbially induced calcium carbonate precipitation: insight into scale dependence of biogeochemical reaction rates[J]. Water Resources Research, 2016, 52(11): 8969-8985.

[49] FERRIS F G, PHOENIX V, FUJITA Y, et al. Kinetics of calcite precipitation induced by ureolytic bacteria at 10 to 20 degrees c in artificial groundwater[J]. Geochimica et Cosmochimica Acta, 2004, 68(8): 1701-1710.

[50] ZHONG S J, MUCCI A. Calcite and aragonite precipitation from seawater solutions of various salinites - precipitation rates and overgrowth compositions[J]. Chemical Geology, 1989, 78(3/4): 283-299.

[51] ZHANG C Y, DEHOFF K, HESS N, et al. Pore-scale study of transverse mixing induced CaCO3 precipitation and permeability reduction in a model subsurface sedimentary system[J]. Environmental Science & Technology, 2010, 44(20): 7833-7838.

[52] NIEL PLUMMER L, BUSENBERG E. The solubilities of calcite, aragonite and vaterite in CO2-H2O solutions between 0 and 90℃, and an evaluation of the aqueous model for the system CaCO3-CO2-H2O[J]. Geochimica et Cosmochimica Acta, 1982, 46(6): 1011-1040.

-

期刊类型引用(8)

1. 褚洪涛. 低能强夯联合水泥土搅拌桩在路基工程中的应用. 广东建材. 2025(03): 122-126 .  百度学术

百度学术

2. 刘齐建,苏耀辉,黄奕彬,邓涛. 地面超载下摩擦单桩负摩阻力的连续介质力学解. 建筑科学与工程学报. 2024(02): 173-180 .  百度学术

百度学术

3. 李子林. 大跨度排架结构储豆堆场地基处理方案研究. 福建建材. 2024(04): 69-72 .  百度学术

百度学术

4. 刘余杰. 水泥土搅拌桩在农村公路桥梁基础施工中的应用研究. 交通世界. 2024(13): 40-43 .  百度学术

百度学术

5. 张浩,赵宇,王中,刘维正. 芯桩承载扩体预制桩的荷载传递计算分析. 岩土工程学报. 2024(12): 2503-2512 .  本站查看

本站查看

6. 周节定,胡磊,王乾浩. 同步同心式斜撑桩侧摩阻力现场试验研究. 建筑施工. 2023(04): 770-772+785 .  百度学术

百度学术

7. 郑贺,鲍宇,刘汉臣. MC劲性复合桩在硬土层中应用的试验研究. 地基处理. 2023(03): 262-268 .  百度学术

百度学术

8. 朱田. 分布式光纤测试技术在水泥土复合管桩检测中的应用. 水利与建筑工程学报. 2023(05): 63-70 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: